Tech Insights

@tech_insights1

Followers

232

Following

114

Media

228

Statuses

1K

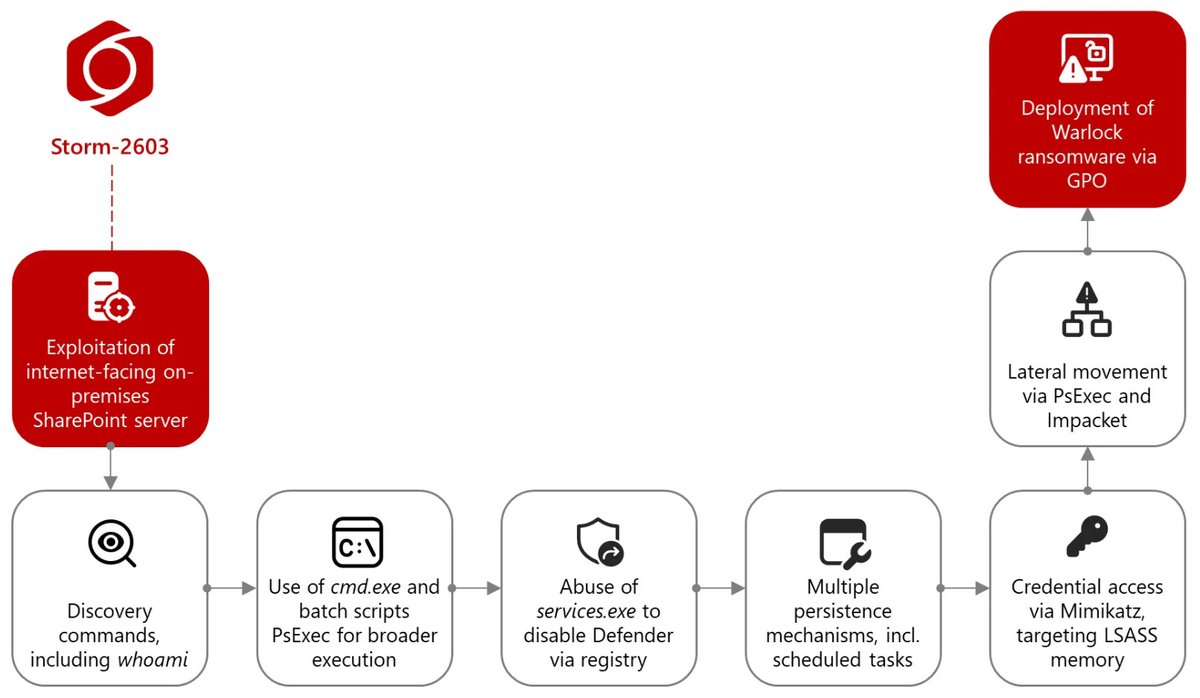

Microsoft Threat Intelligence team share details of Storm-2603 activity that leads to the deployment of Warlock ransomware by exploitation of on-premises SharePoint vulnerabilities CVE-2025-49706 & CVE-2025-49704. https://t.co/ZjVX7XqI5o

0

25

66

🚨 BREAKING: The US National Nuclear Security Administration - the agency responsible for maintaining and designing nuclear weapons - was breached in the Microsoft SharePoint hack. We literally just published a video explaining why data centers are nuclear first-strike targets

7

12

29

Mystery solved!! Ubuntu 22.04 had an automatic update to systemd. This update restarted systemd that wiped IP rules and took down networking for Kubernetes infra. The update came out 9 June. 9-10 June dozens of services had big outages. Like Heroku:

newsletter.pragmaticengineer.com

What are the lessons of large outages at Heroku, Google Cloud, and Neon? Plus, how responses to outages can be as informative as incidents themselves…

What is happening right now? ChatGPT/OpenAI outage for 3 hours Heroku down for 4 hours (even their status page is down!) NVIDIA dev docs as well (runs on Heroku) Pipedrive (CRM) issues for 4 hours What else is down… and are these connected? Something started 4 hours ago…

65

284

2K

The Best Project Management Tool Ever: https://t.co/oZo6r0Yfma A Must-Have Tool For Project Managers RePost Please and like Please #project #management #projectmanagement

4

14

67

Think and introspect. What exactly are you doing in the name of your stock position maintenance and warehousing logics. Again, remember, it's not the operations part which I am talking about but the IT system. And check what can be optimized in your whole system.

0

0

0

I won't talk about EOQs and all those. Those require a bit of complex logic(I know of a company where a person who was on leave wrote the whole allocation system for a business submodel to kill time - other words, even that's not that complex. Complex, but not too complex).

1

0

0

I know Python is not the language because of scaling issues but the real question is, if the logic is that straightforward and simple, what exactly are we doing in the name of WMS and stock quantity derivation?

1

0

0

Where I felt really bad was, a few weeks ago, in a way to kill time, I decided to write a WMS system. And that too, of all languages, in Python. 90% of the warehouse receiving logic, including front end design is completed in what? 300 lines?

1

0

0

3. Everything else is a stock transfer order - just drive it through a stock movement type(Return to Warehouse from Store, Send it to the Quality Site, Is the receiving site a storage site or a pass through site - and all those).

1

0

0

Don't think of a hundred routing logics. All you need to remember here is, 1. If the source is not you, it's a purchase order and you need to pay for it 2. If the destination is not you, it's a sale order and you need to invoice that

1

0

0

The next aspect of the mess we see in supply chain management is the information which you need. If you are not the warehouse, don't hoard the information. All you need is a source, source type, destination, destination type, transaction reference, product reference and quantity.

1

0

0

This information is more than enough to build the stock position. But then, to derive this, I see complex logics and jobs running for hours to derive these final numbers. Why exactly are we complicated things that much and tying ourselves in knots?

1

0

0

And coming to stock in transit. What is that? 1. Quantity yet to be received 2. Goods Issue Quantity which is yet to be system processed - this is applicable only for stores because you receive Goods Issue anyways as a part of system ASN - which is vehicle dispatch.

1

0

0

Available Quantity = Total Quantity - Quality Stock -Blocked Stock - ordered stock - (reservation qty - reservation delete qty). How do you change total quantity? Goods Receipt - Goods Issue + Stock Adjustments

1

0

0

Nothing else is needed beyond this. The next level is, what is warehouse stock position? Stock available for picking. Now, if you use an ERP like SAP to manage this stuff without using EWM, what do we see?

1

0

0

I tend to see solution design is overcomplicated these days. For example, consider the case of stock availability. What do you suppose should be the inputs? 1. Warehouse stock position 2. What's the stock in transit?

1

0

0

decided to capitulate and then come to each one of us personally justifying his stand.

0

0

1

and the contact centre misheard it as NT? Complete silence in the room. And I say, when we have historic cases where such mistakes did not happen, on what basis are we saying it's happening this time? And I leave the room. It's a different thing, however, that the project owner

1

0

1