Danny Kelly

@dannykelly1978

Followers

3K

Following

4K

Media

263

Statuses

1K

Professor of Tissue Engineering @tcddublin. PI in @TCDtcbe and @ambercentre. Tissue engineering / 3D Bioprinting cartilage, bone and joints

Dublin City, Ireland

Joined June 2015

New lab website now live: https://t.co/B3FTC2wxIZ Other lab related sites: https://t.co/7aAnMvCU0l

https://t.co/ZKla4EJZ1i

kelly-lab.com

Kelly Lab

0

12

40

We have open Postdoctoral Researcher and PhD Positions in 3D Bioprinting and Tissue Engineering in our lab at Trinity College Dublin. More details below 👇 @ambercentre @tcdTCBE @tcdTBSI @tcdengineering

2

56

146

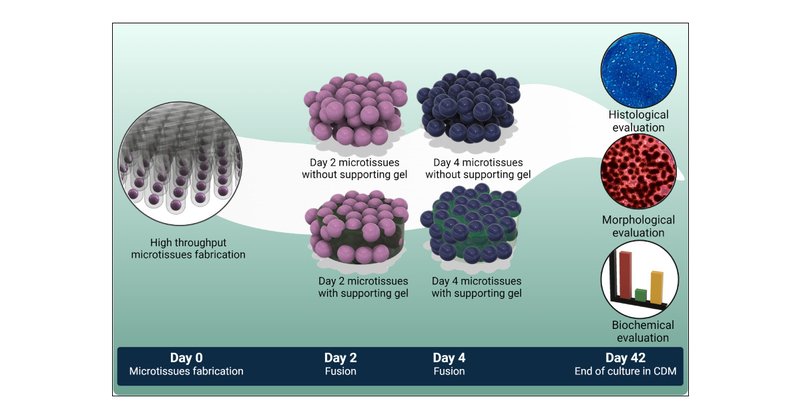

📣 New paper alert! ‼️Happy to share our recent paper that explored the use of hydrogels to support the biofabrication and 3D bioprinting using cartilage microtissues @dannykelly1978. Huge thanks to the brilliant co-authors that made it possible ⭐️

pubs.acs.org

In recent years, there has been increased interest in the use of cellular spheroids, microtissues, and organoids as biological building blocks to engineer functional tissues and organs. Such microt...

1

6

37

Research Fellow 3D Printing #Biomaterials & Tissue Engineering Work in AMBER in @BuckleyLabTCD & @dannykelly1978 Labs Project Title: 3D Printed Collagen-Based Surrogate Lumens for Enhanced Surgical Training https://t.co/75XNSNY5ZQ

#materialsforhealth #bioengineering

0

5

13

Today on International Childhood Cancer Day #ICCD🎗️I’m fortunate enough to announce 📣 Two @ERC_Research funded PhD projects 📣 focused on #Osteosarcoma. #jobfairy If you’re interested in developing organ-on-chip disease models for drug discovery please apply!

2

25

60

A hybrid scaffold was developed by @dannykelly1978 and team by merging two different additive manufacturing methods. The microfibrous core guides bone healing, while a stiff outer shell offers mechanical support and accelerates healing. Learn more: https://t.co/pbPoXngtvX

0

5

66

Congratulations to my good friend @LaoiseMcnamara on receiving the @RAMIreland Silver Medal for delivering a wonderful Haughon Lecture at @bini_irl conference #BinI2024

0

3

41

🔬 Altach Biomedical, a spin-out from @tcdTCBE, aims to transform cartilage repair with collagen scaffold tech. Over 15 years of research, now crowdfunding to accelerate impact! Invest in innovation 👉 : https://t.co/P0etd96REg

0

10

26

Huge congratulations to head of TERG @fjobrien and @dannykelly1978 on the Ambassador Recognition Award they received last night for their work on the @WCB2018 at Fáilte Ireland's Conference Ambassador Recognition Awards! 🥳

1

9

66

An iterative MEW process was then implemented to print scaffolds with a wedged-shaped profile similar to the meniscus, into which we deposited iMPCs and oMPCs in a spatially controlled manner. This process allowed us to 3D bioprint biomimetic fibrocartilage constructs.

0

1

6

Furthermore, by using MPCs isolated from the inner (iMPCs) and outer (oMPCs) zone of the meniscus, we were able to bioprint phenotypically distinct constructs mimicking aspects of the native tissue.

1

1

3

By depositing MPCs within melt electrowritten (MEW) scaffolds with elongated pore shapes, which functioned as boundaries to direct cell growth and extracellular matrix production, we were able to bioprint anisotropic fibrocartilaginous tissues with preferentially aligned collagen

1

1

5

Here we investigated zone-specific meniscus progenitor cells (MPCs) for bioprinting functional meniscal tissue. We first confirmed that MPCs from the inner (iMPCs) & outer (oMPCs) regions of the meniscus maintain their differentiation capacity with monolayer expansion.

1

1

4

New lab paper led by @xbarcelo95 just out in @Biofabrication : 'Bioprinting of scaled-up meniscal grafts by spatially patterning phenotypically distinct meniscus progenitor cells within melt electrowritten scaffolds' https://t.co/wILY1bvibc

2

8

58

In an additional group, hybrid scaffolds were also functionalised with BMP2, which further accelerated healing and facilitated the complete defect bridging after 12 weeks. These scaffolds supported the formation of well-defined annular bone, with little evidence of ectopic bone.

0

0

1

Compared to MEW scaffolds alone, hybrid scaffolds prevented soft tissue collapse into the defect region and supported increased vascularization and higher levels of new bone formation 12 weeks post-implantation.

1

0

2

The scaffolds were then coated with pro-osteogenic calcium phosphate (CaP) nano-needles, which were later used to facilitate the binding and controlled release of bone morphogenic protein 2 (BMP2).

1

0

2

Here we combined melt electrowriting (MEW) and fused deposition modelling (FDM) to fabricate hybrid scaffolds for bone defect healing. MEW was used to fabricate a microfibrous core to guide bone healing, while FDM was used to fabricate a stiff outer shell for mechanical support.

1

1

4

New lab paper led by @KianEichholz just out in Advanced Healthcare Materials: ‘Integrating melt electrowriting and fused deposition modelling to fabricate hybrid scaffolds supportive of accelerated bone regeneration’ https://t.co/k4pXGldjwu

3

15

105

This supported enhanced microtissue (re)modelling and enabled the development of a more biomimetic tissue with a zonally organised collagen-network. Additionally, enzymatic treatment modulated matrix composition, tissue phenotype, and to a lesser extent, tissue mechanics.

0

0

6