Srivastava Lab at UCLA

@_SrivastavaLab

Followers

234

Following

41

Media

10

Statuses

54

Electrostatic Self-assembly | Polymer Upcycling | Department of Chemical & Biomolecular Engineering at UCLA | PI: @samanvaya

Los Angeles

Joined May 2023

We are cxcited to represent UCLA Chemical & Biomolecular Engineering at the #APS2025 Global Physical Summit @APSPhysics! 🚀 Our group will present 9 talks + 4 posters showcasing our latest research. Check out our lineup, and we hope to connect with you there!

0

2

11

The result? Cross-linkable polymers that gel rapidly and achieve robust adhesion across diverse surfaces - marking a stark enhancement in properties compared to conventional catechol-based wet adhesives. Dive into the full details of our work here: https://t.co/79RHO0IVgC

0

1

3

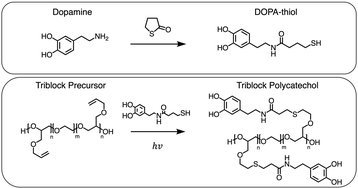

In this work, we utilize ring opening polymerization and thiol-ene click chemistry to produce triblock polycatechol (tbPC) - polymers that feature high density of catechol endblocks bridged with a hydrophilic PEG middle block.

1

1

3

Biomimicry of marine organisms’ adhesive systems have paved the way for numerous material discoveries based on the versatility of catechol chemistry. But difficulty in the synthesis of catechol-based polymers remains a challenge limiting their effectiveness and tunability.

1

0

2

Our latest publication in @ChemCommun , led by @FahedAlbreiki , introduces a modular synthesis of catechol-containing triblock copolymers that form strong and wet adhesives! https://t.co/79RHO0IVgC

@UclaCBE @UCLAengineering @UCLA #NSFfunded #MusselAdhesion #Hydrogels

pubs.rsc.org

We report the synthesis of catechol-functionalized symmetric triblock polymers comprising densely functionalized catechol endblocks using anionic ring-opening polymerization (AROP) and thiol–ene...

1

8

25

Advait developed this innovative technology in his graduate research. Join us in supporting this solution to reduce CO2 emissions and drive sustainable aviation! 🌍✈️ https://t.co/ZukzEY924P

#TechInnovation #SustainableAviation #Praio #uclasamueli #ucla #activate (2/2)

activate.org

Praio will economically manufacture bio-derived commodity chemicals, such as aviation fuel, using synthetic protocells with a reduced carbon footprint.

0

4

8

Excited and proud of Advait Holkar, a graduate of our lab, who has been selected as an Activate Fellow! He is launching Prāio Inc., which will focus on enabling low-cost production of sustainable aviation fuel (SAF) through a pioneering protocellular biocatalysis platform (1/2)

1

4

16

🚀 The latest study from @samanvaya's group shows that comb polyelectrolyte stabilizers improve coacervate microdroplet stability for drug delivery. Thanks to @BioPACIFICMIP, high-throughput materials characterization was possible. https://t.co/fLAbzBk0pc

@softmatter

@cnsiatucla

0

3

6

An increase in the salt resistance of the coacervates upon introduction of cPEs is seen to be maintained over 15 days, underlining the role of cPEs in imparting and maintaining stability over extended durations. (6/6)

0

0

1

Number density and avg. microdroplet size are shown to be controlled by varying the cPE and salt concentrations. Turbidity maps, akin to binodal phase maps, depict an expansion of the turbid two-phase region. (5/6)

1

0

1

By monitoring the temporal evolution of dispersion turbidity, we show that cPEs suppress microdroplet coalescence with minimal change in microdroplet sizes over 48 h, even at salt conc. up to 300 mM. (4/6)

1

0

0

Stabilizing complex coacervate microdroplets is desirable due to their various applications (e.g., bioreactors, drug delivery vehicles, and encapsulants). The stability of the dispersions is shown to be modulated by concentrations of comb polyelectrolyte (cPE) stabilizers & salt.

1

0

0

Congratulations to graduate student Advait Holkar, lab alum Dr. @ShangGaoCBE and undergraduate researcher Kathleen Villaseñor! (2/6)

1

0

0

Our work on using quantitative turbidimetry for characterizing stabilized complex coacervate dispersions using automation is out in @softmatter

https://t.co/TrQ7wAa5n7

@UclaCBE @BioPACIFICMIP @cnsiatucla @UCLAengineering @UCLAnewsroom @samanvaya @ShangGaoCBE (1/6)

pubs.rsc.org

Stabilizing complex coacervate microdroplets is desirable due to their various applications, such as bioreactors, drug delivery vehicles, and encapsulants. Here, we present quantitative characteriz...

1

2

14

Our group members spent a fun afternoon at the Willows Community School’s Sunday Funday with 100+ kids excited to learn about polymers, surface tension and complex fluids!

1

3

26

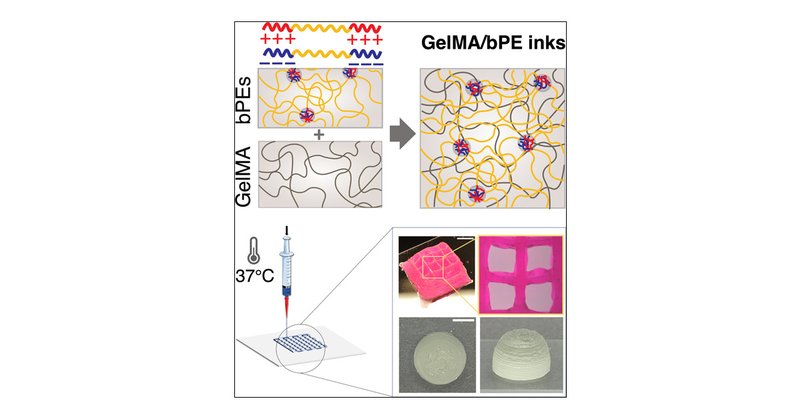

🔬 The latest paper from @BioPACIFICMIP researchers @FahedAlbreiki and @samanvaya from @UCLA in collaboration with project scientist Juan Manuel Uruena reveals how block polyelectrolyte additives enhance #3Dprinting of biopolymer inks. Read it here:

pubs.acs.org

We demonstrate the utility of block polyelectrolyte (bPE) additives to enhance viscosity and resolve challenges with the three-dimensional (3D) printability of extrusion-based biopolymer inks. The...

0

5

9

Our work on enabling 3D printability of gelatin inks in physiological conditions by utilising self-assembled block polyelectrolytes scaffolds is out: https://t.co/ee2Sc2y98R Congrats to Tobias, @FahedAlbreiki, @DefuLi8 & Alisa! @samanvaya @UclaCBE @BioPACIFICMIP @ACSPublications

pubs.acs.org

We demonstrate the utility of block polyelectrolyte (bPE) additives to enhance viscosity and resolve challenges with the three-dimensional (3D) printability of extrusion-based biopolymer inks. The...

2

5

30

We provide insights about their viscoelastic properties and 3D printability assessments. Thanks to our collaborators at @KITKarlsruhe and @BioPACIFICMIP for their valuable contributions! @UclaCBE @UCLAengineering

0

0

2

We developed inks comprising gelatin and block polyelectrolyte scaffolds that were printable at physiological temperatures in commercial extrusion-based printers w/ high resolution (<0.5 mm).

1

0

2

Additive manufacturing of gelatin hydrogels is desirable for applications ranging from tissue engineering to food science. But gelatin inks suffer from low viscosity and poor printability at physiological temperatures.

1

0

3