Matthew Hartensveld, PhD

@MattHartensveld

Followers

3K

Following

465

Media

46

Statuses

81

Posts related to homebrew semiconductor device fabrication and semiconductor news.

Rochester, NY

Joined January 2014

Goodbye wooden table, the sputtering system has officially moved into the lab with a few new upgrades.

0

1

23

Updated with the raspberry pi touch screen, now I don't need another PC, I just need to shove all the excess cables for the robot in a project box to clean it up

0

0

8

Basic robotics integration for more repeatable photoresist development on small semiconductor samples. Will move the program over to a touch screen RPi 4 for ease of use.

9

3

58

Built a micro-scale @GamersNexus logo in my home cleanroom. Fan-made, not affiliated; just for fun.

1

0

6

Needed DI water for the cleanroom shed, fixed a water polished and built a DIY water station in my basement City water -> Water Softener -> CF/RO system -> resin filter -> elga water polisher = DI water <3 PFA containers to keep it DI and transport to/from shed

2

0

19

Constructed over the course of a few months in whatever free time I could find. Learned lots of new skills along the way. Key factors are cleanroom grade flooring, epoxy painted walls, positive pressure filter air intake, and lots of airflow with 2 FFUs.

8

6

458

Sputtering system I built into a wood table haha, working on extruded Al build before I add to the lab

2

3

194

RIE etching with flourine based gases with modified desktop sputter system.

9

3

229

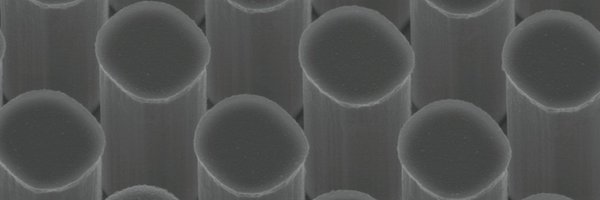

Lithography through custom i-line stepper from a modified microscope. Can do dry sub-micron or immersion for down to ~100nm (though with hit to field size)

13

10

484

Class 100 Cleanroom Shed I Built For Semiconductor R&D :)

252

491

9K

Built a new spin-coater with a custom UI, it makes use of an internal pump for vacuum with just one external cable for power.

1

0

40

Automation in progress + sub 100nm features?

0

0

11

New chamber "hat" to make room for the sputter gun

0

0

5