thrutheframe

@thrutheframe

Followers

604

Following

49

Media

330

Statuses

731

Cloud ninja. into photography, CAD & 3D printing.

Singapore

Joined November 2019

Don't wanna be here?

Send us removal request.

Explore trending content on Musk Viewer

#RafahOnFıre

• 1672331 Tweets

Israël

• 1262649 Tweets

Memorial Day

• 453013 Tweets

اسرائيل

• 409679 Tweets

LISA x KITH WOMEN

• 183075 Tweets

ミサイル

• 128943 Tweets

Kabir is God

• 101533 Tweets

Sakamoto Days

• 93258 Tweets

Pablo Iglesias

• 88177 Tweets

Nadal

• 67364 Tweets

Maresca

• 67350 Tweets

#rolandgarros

• 64969 Tweets

Jアラート

• 57996 Tweets

Egyptian

• 53704 Tweets

Jalisco

• 48958 Tweets

السيسي

• 45120 Tweets

Jarabe

• 35328 Tweets

علي الحدود

• 28329 Tweets

Zverev

• 26471 Tweets

Leicester

• 26068 Tweets

OUR BLOOMING STAR MATTHEW

• 24803 Tweets

EURO 2024

• 24368 Tweets

Edomex

• 18190 Tweets

KING KONG IS HERE

• 17272 Tweets

جندي مصري

• 14615 Tweets

Piers

• 13909 Tweets

المتحدث العسكري

• 13238 Tweets

Alejandra del Moral

• 12969 Tweets

#شكرا_للسيد_المندلاوي

• 12561 Tweets

そーちゃん

• 11630 Tweets

GambleFi 3.0

• 11020 Tweets

Human Scum

• 10450 Tweets

Last Seen Profiles

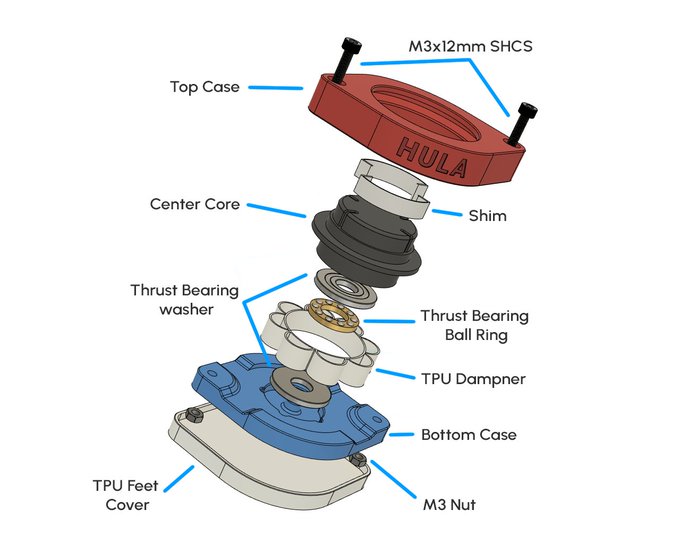

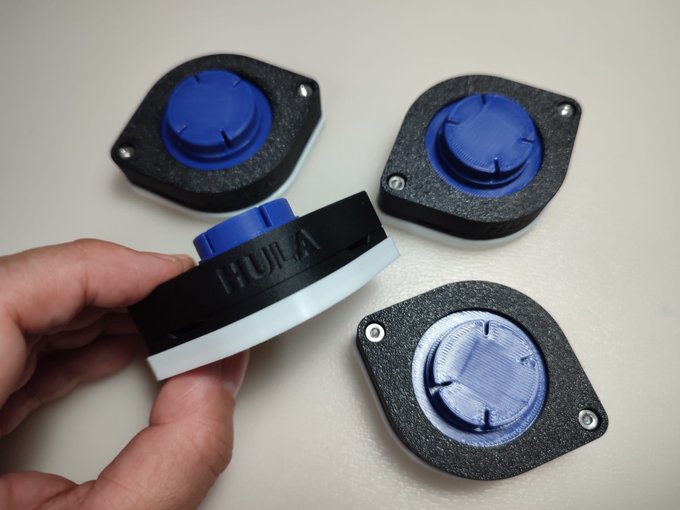

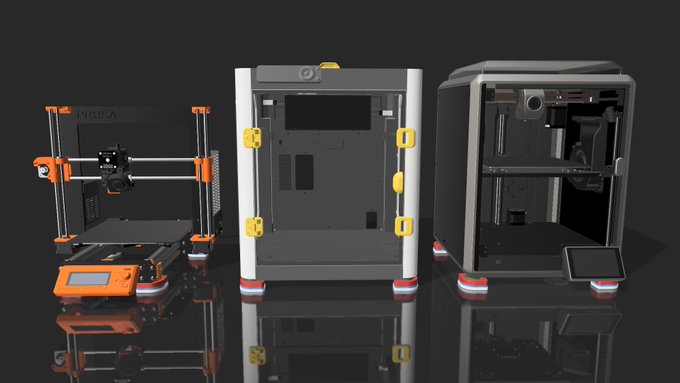

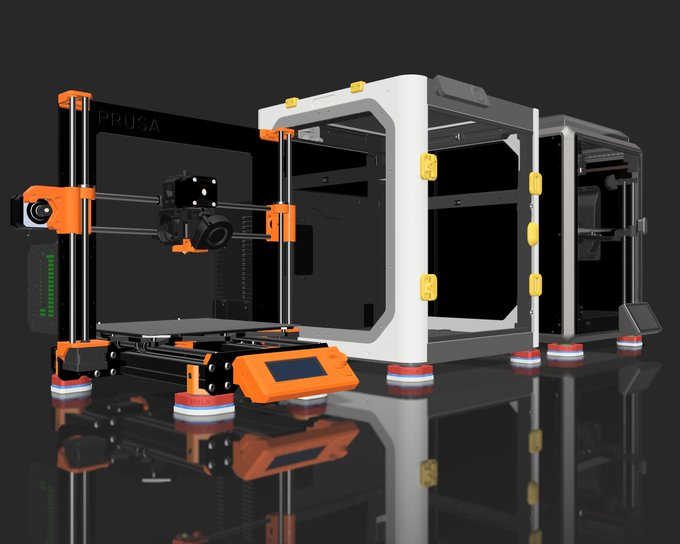

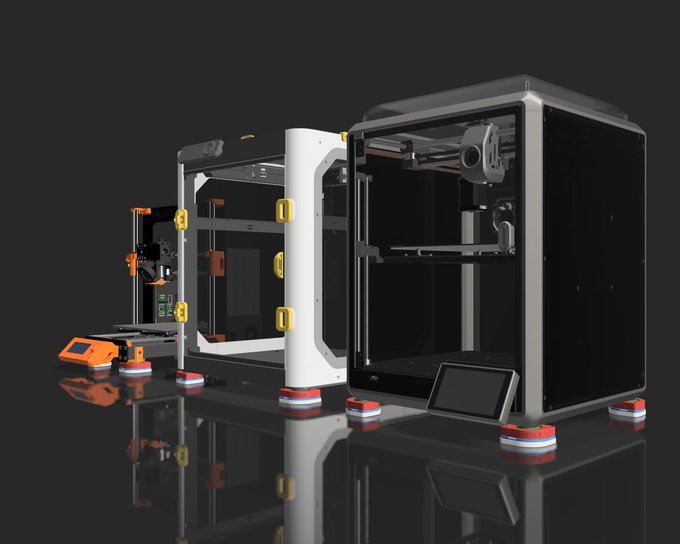

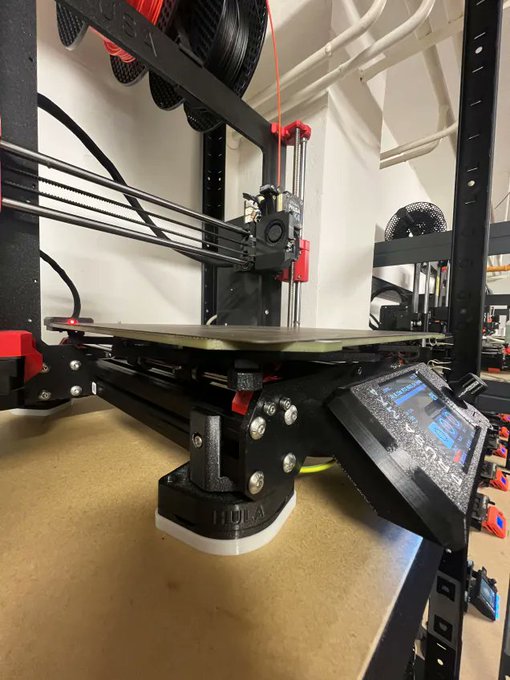

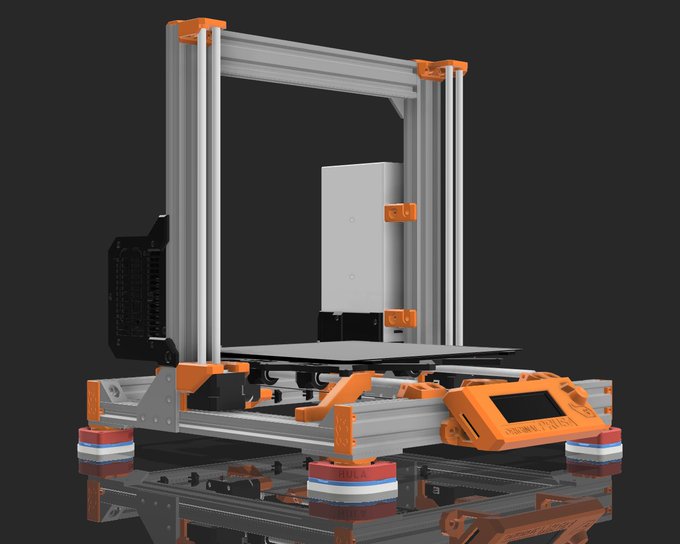

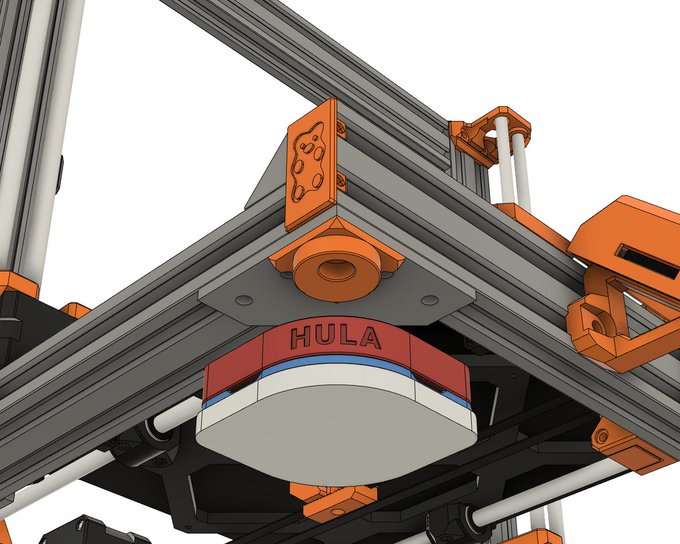

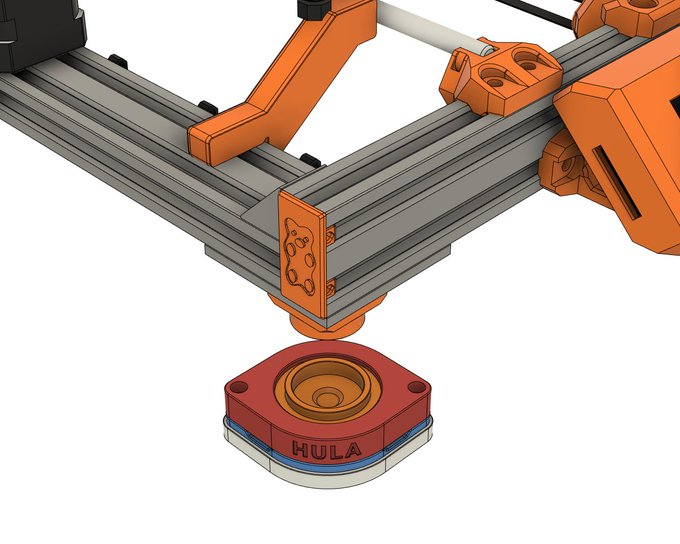

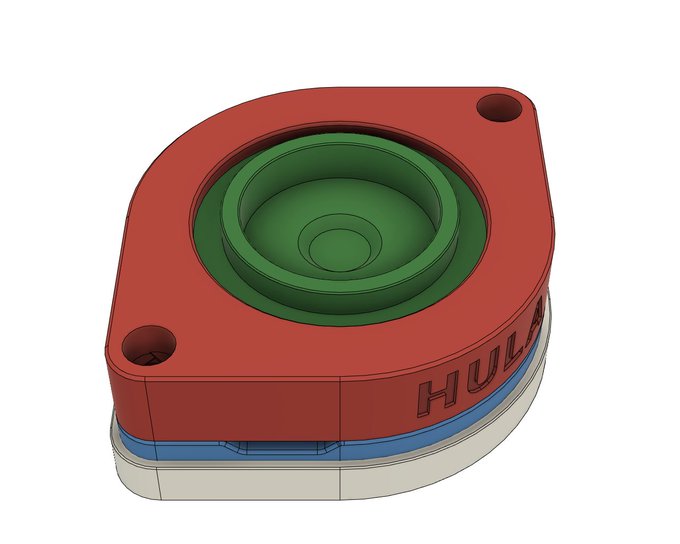

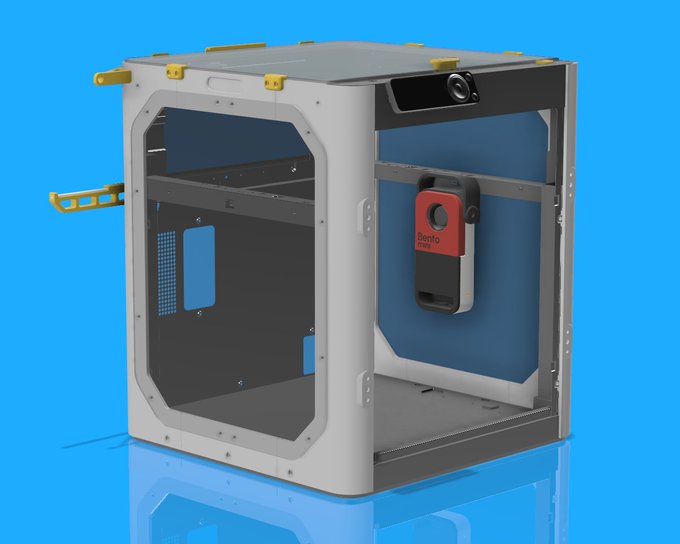

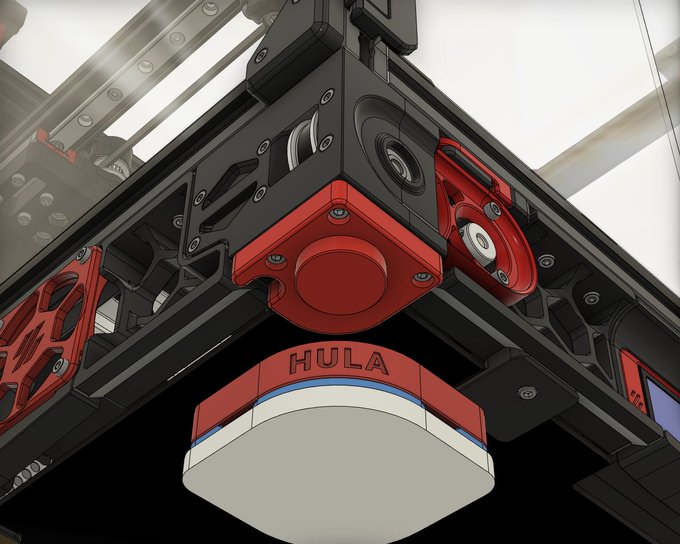

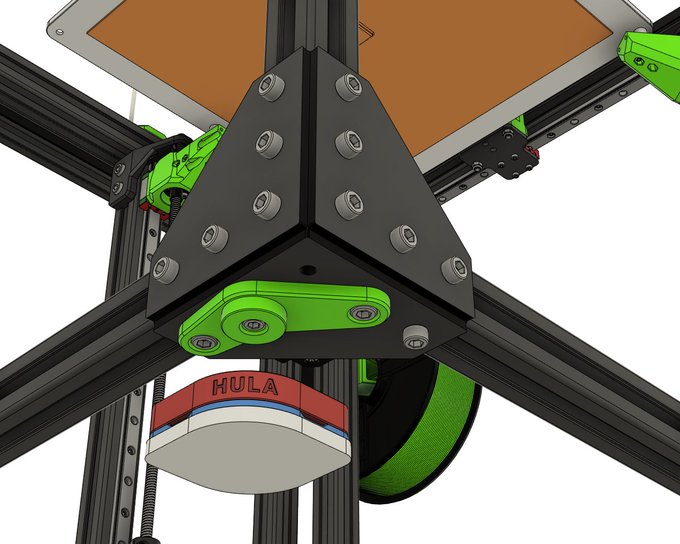

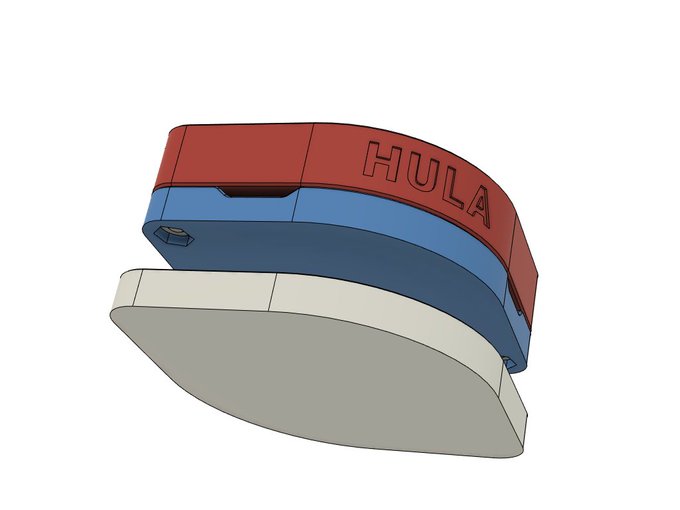

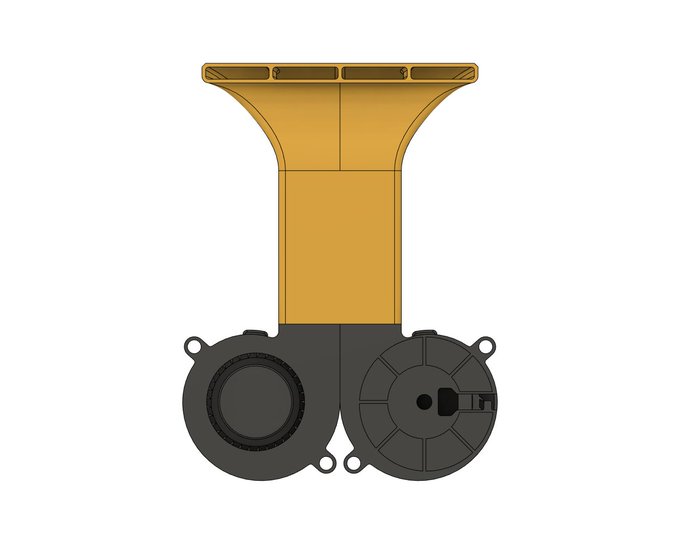

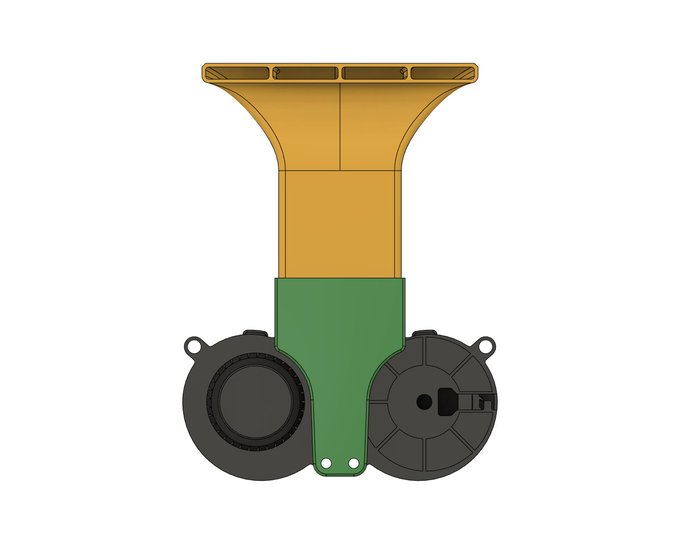

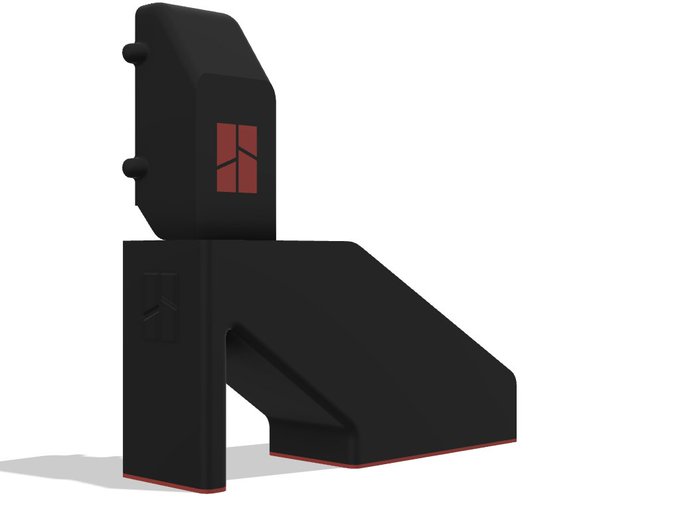

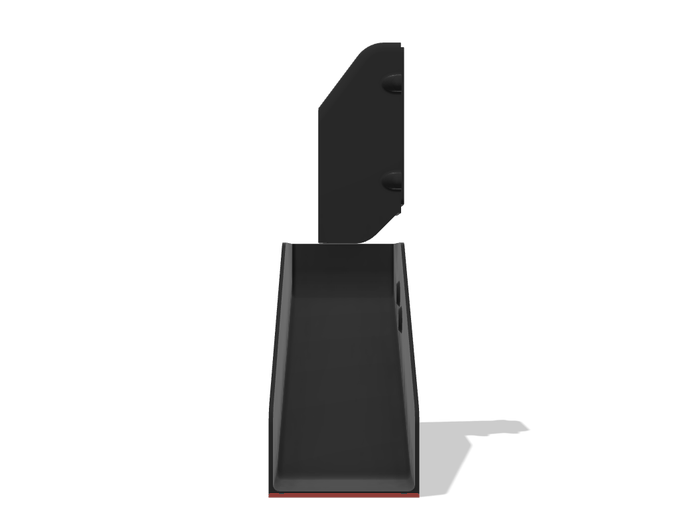

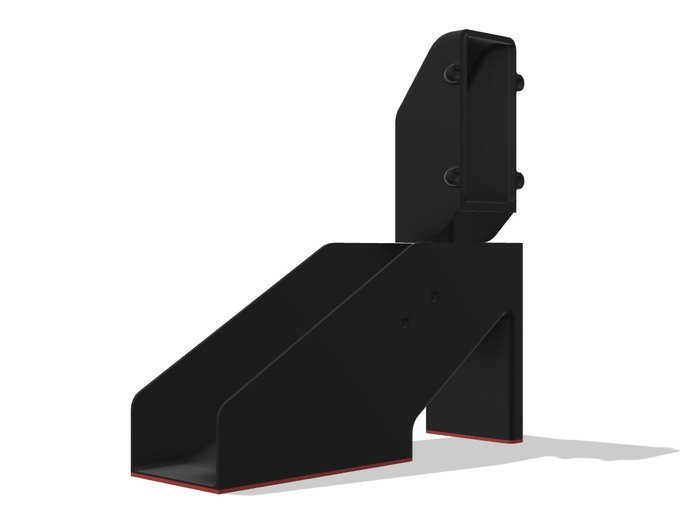

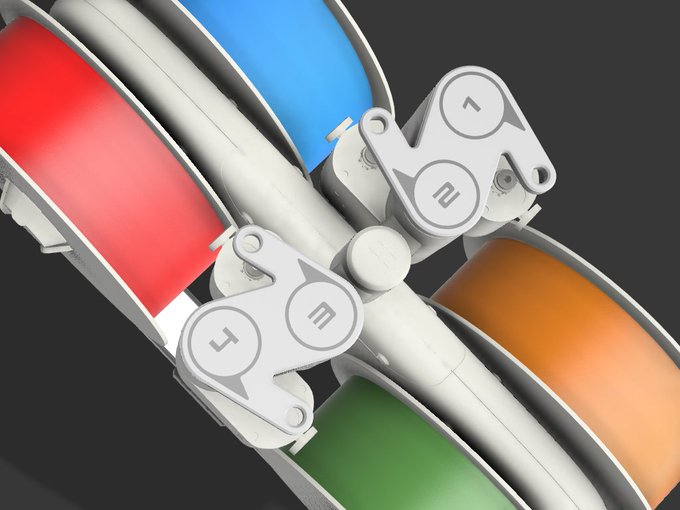

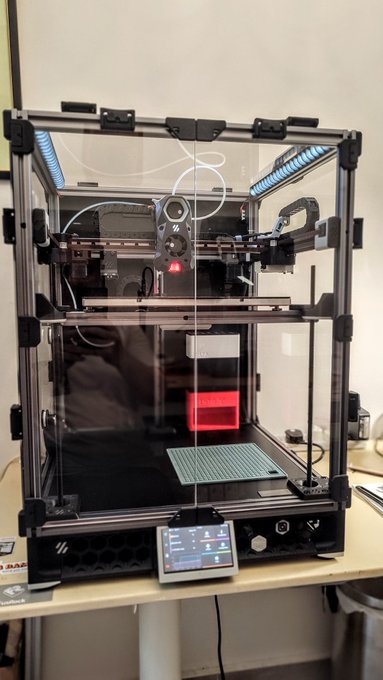

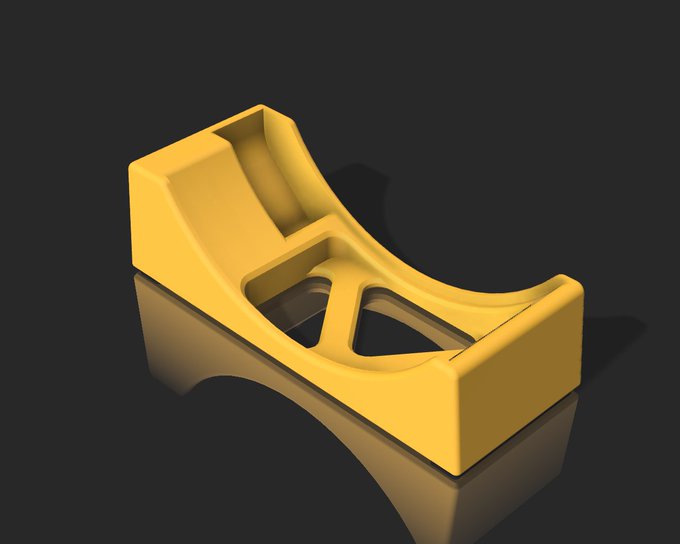

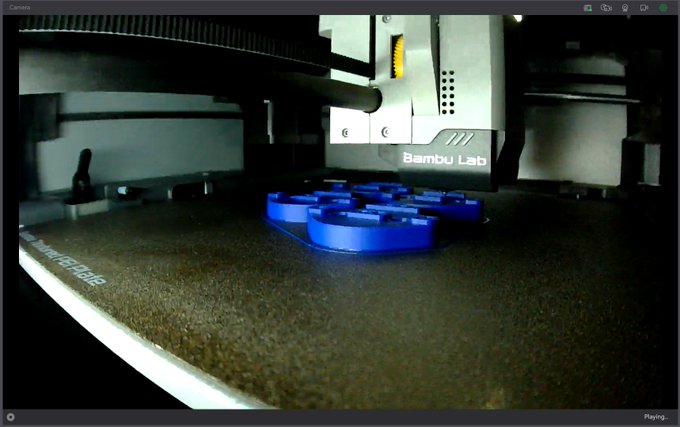

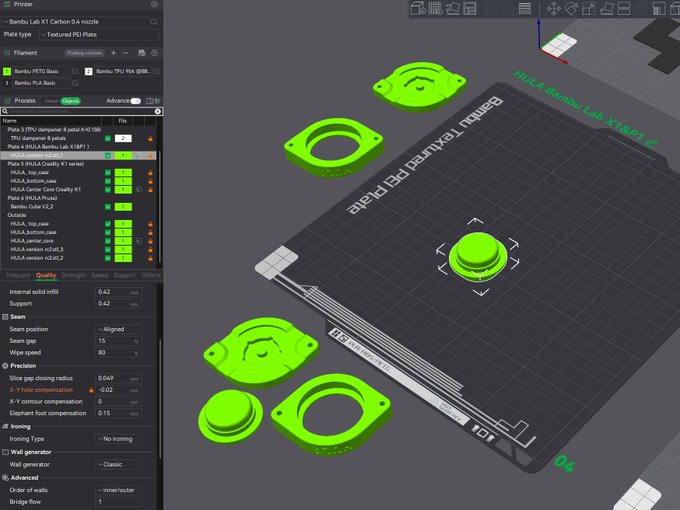

I decided to design anti-vibration feet for

@BambulabGlobal

printers. Drawing inspiration from seismic isolators used in earthquake zone buildings, I designed HULA, an Omnidirectional Self-Aligning Anti-Vibration Foot. Video shows BL anti-V feet (left) vs HULA (right) (1/2)

6

22

187

Using

@CNC_Kitchen

ringing test to compare HULA feet (top) and stock feet (bottom) on the P1P+AMS. Slicer settings were stock & flow dynamic calibration was done for stock feet only. No significant difference on X, noticeable surface improvement on Y.

3

10

65

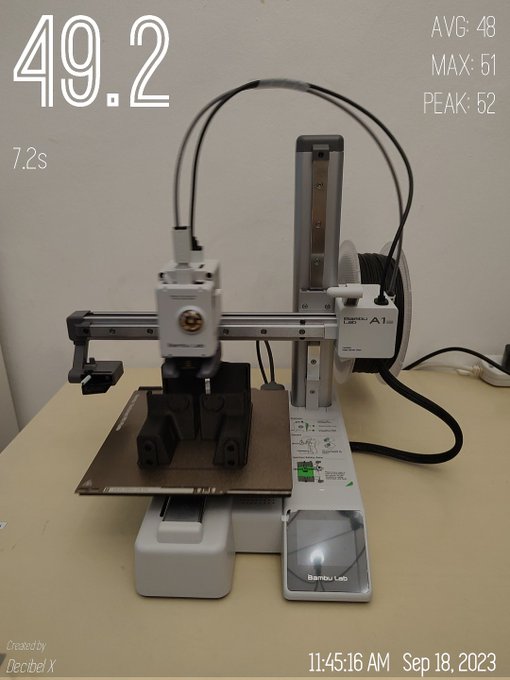

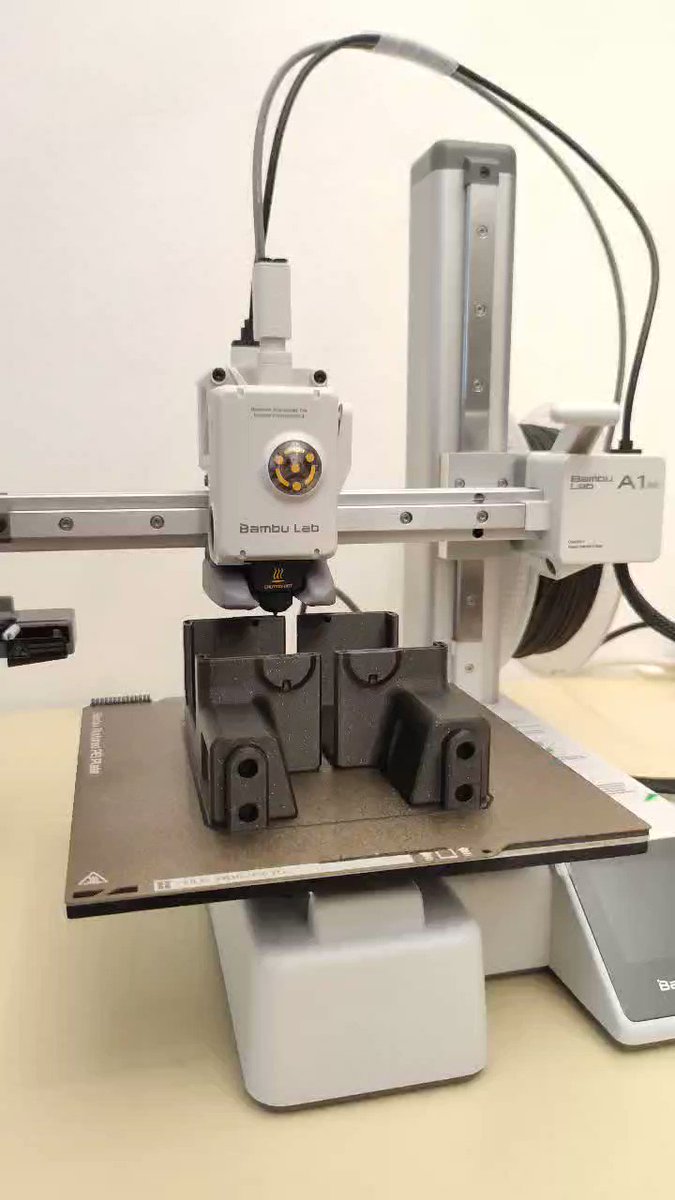

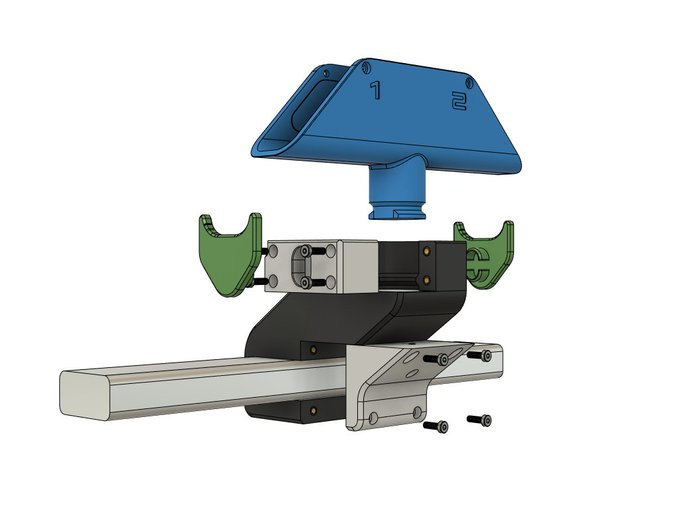

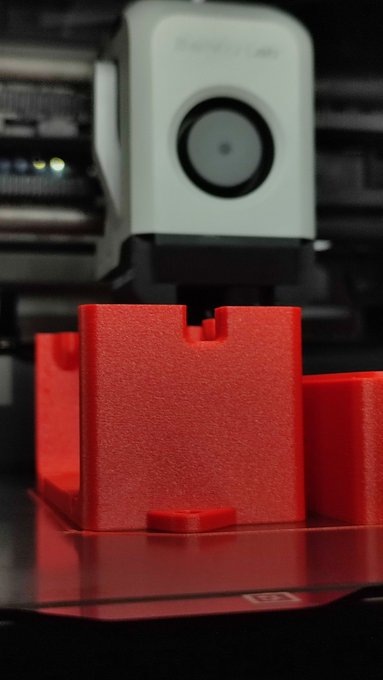

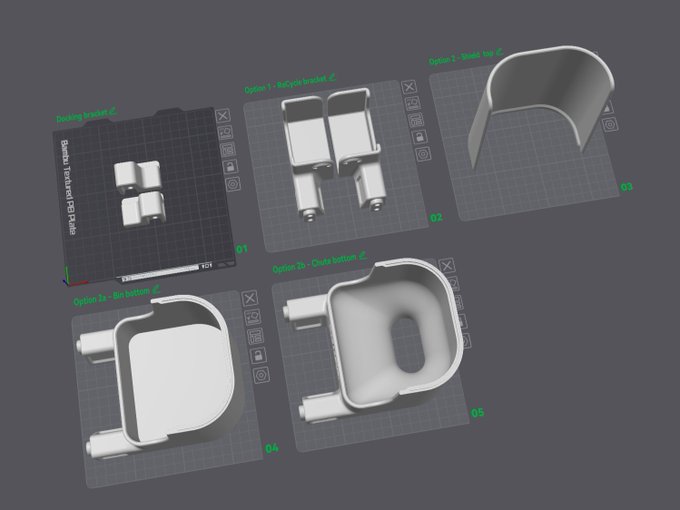

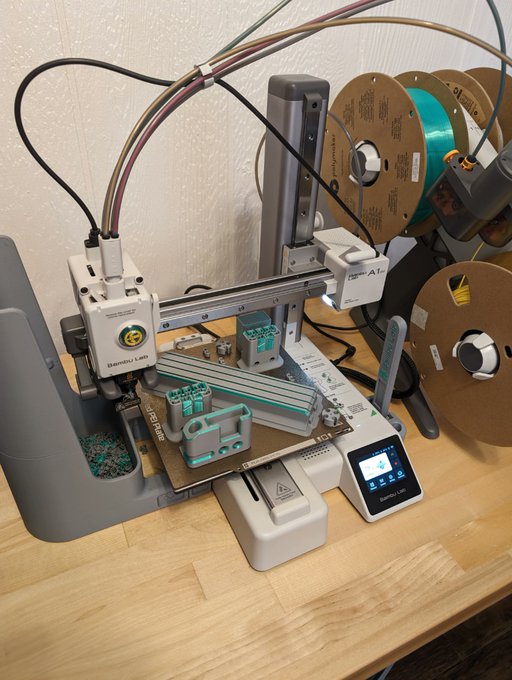

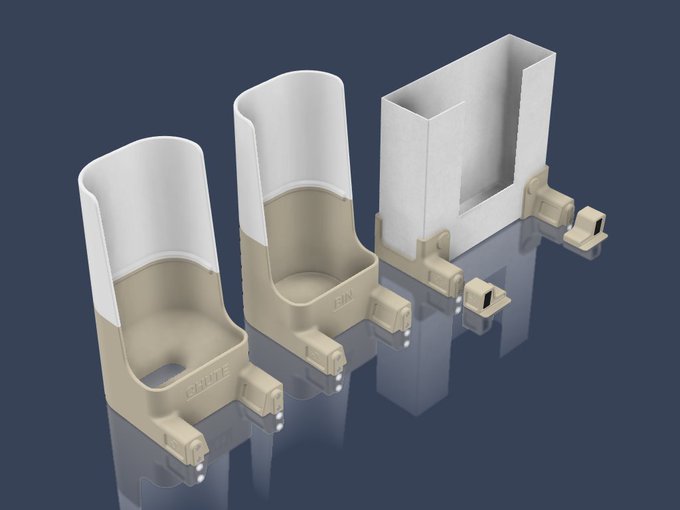

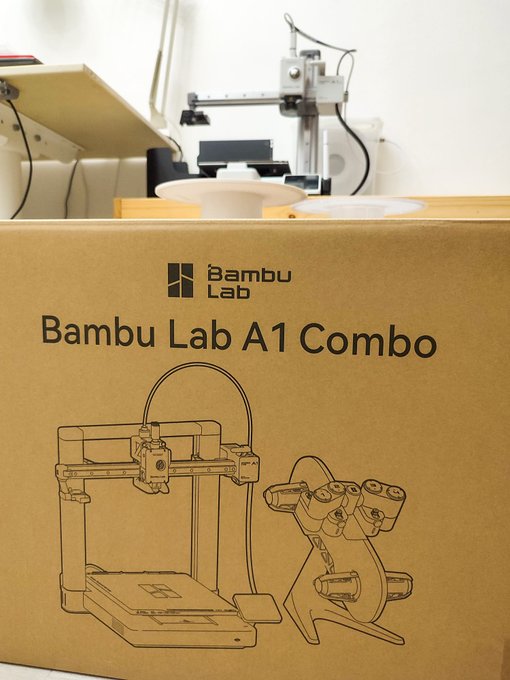

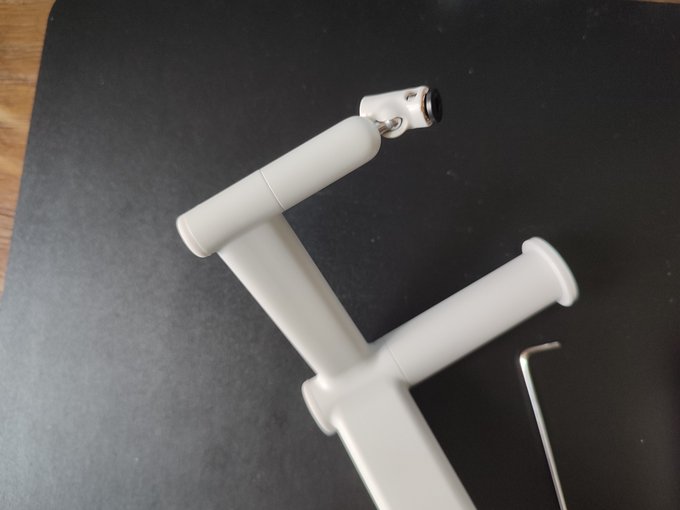

Can the new

@BambulabGlobal

A1 combo have a smaller footprint? Yup. Poop bin and the GRIP bracket, and yes. it swivels. More info in the coming days.

@BambulabJapan

#A1combo

1

9

63

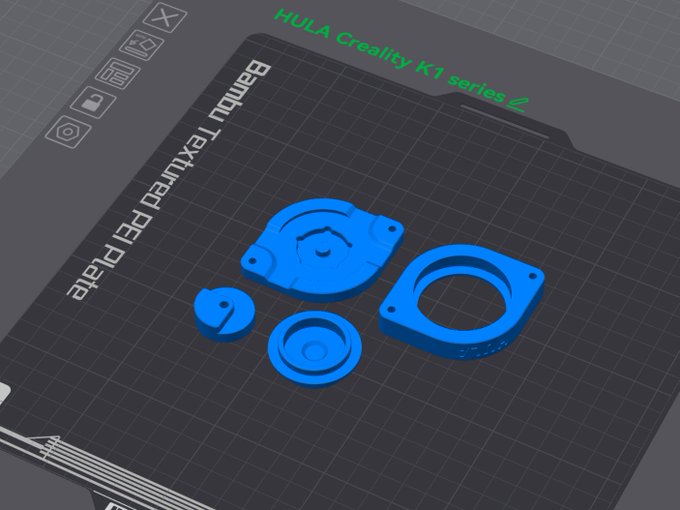

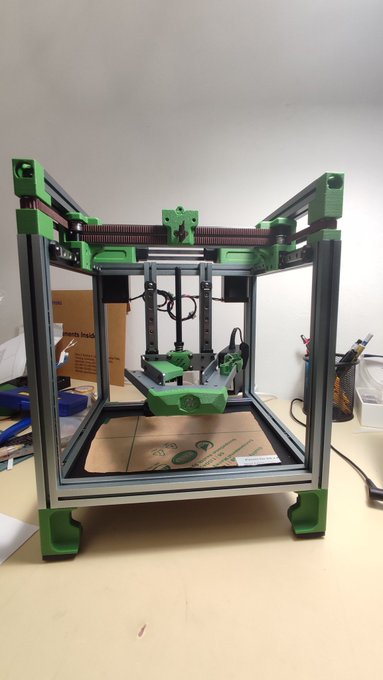

I designed HULA to be compatible with popular 3D printers that the community uses. HULA for Prusa will be launched this weekend.

@josefprusa

@Prusa3D

@BambulabGlobal

@Creality3dprint

3

10

57

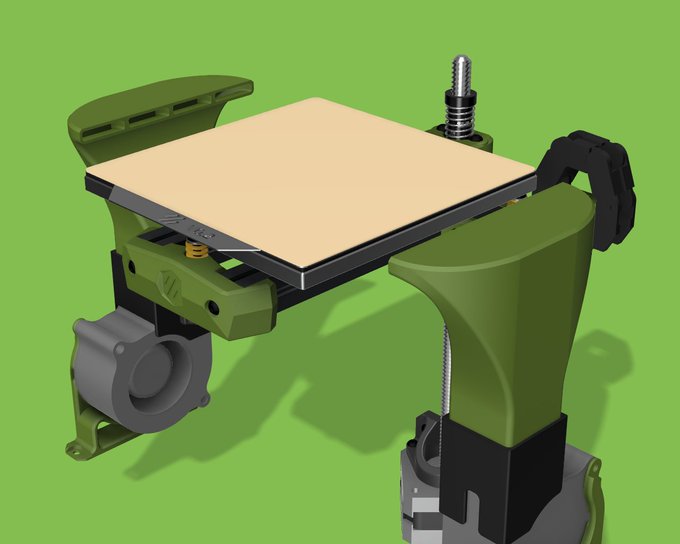

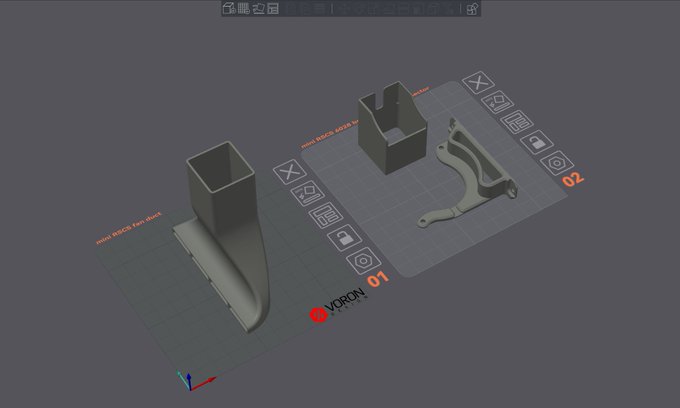

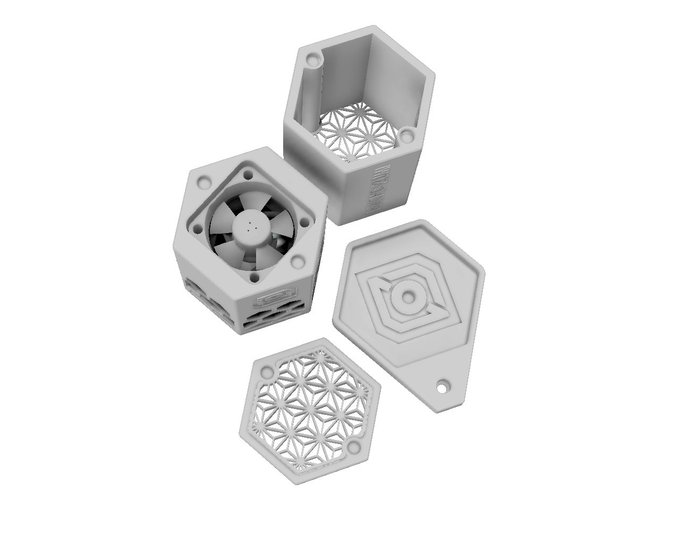

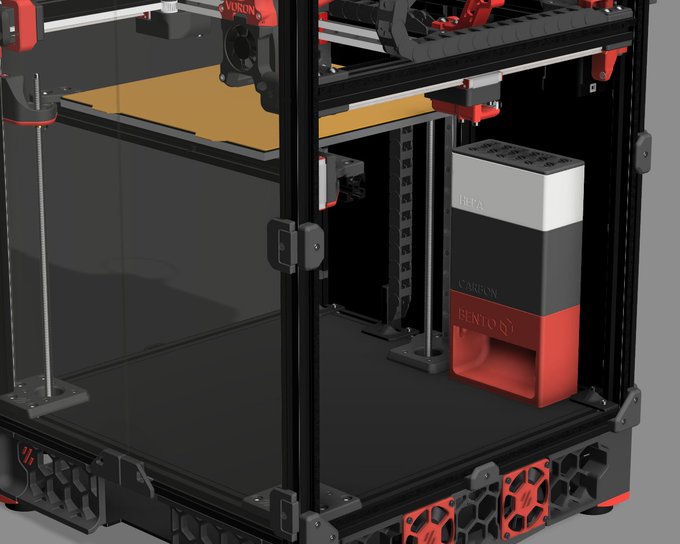

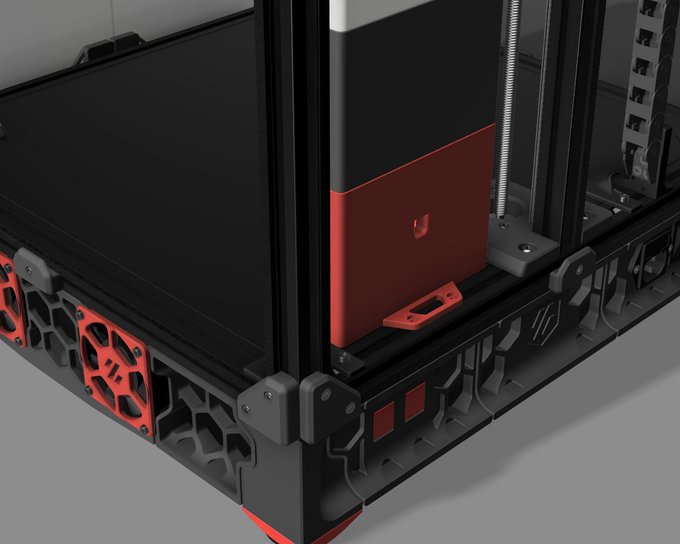

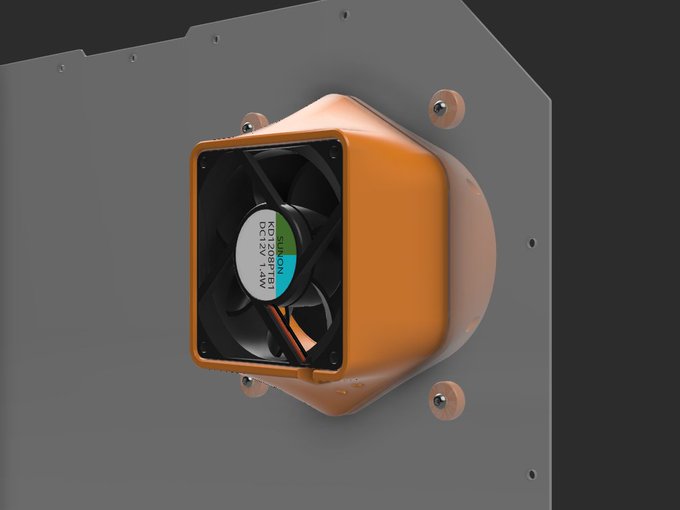

Down down the rabbit hole I go😅. Designed this mini RSCS using 6028 blower fan. Fits a V0 bed, prints flat and no support needed. Have I done CFD? Nope, don't care. Just going to blast air and finger-crossed. 🤣

@Voron_Design

@LDOMOTORSJASON

5

8

56

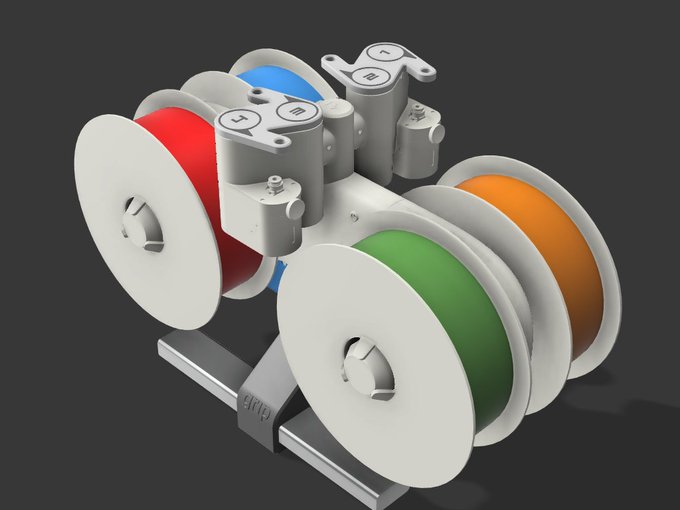

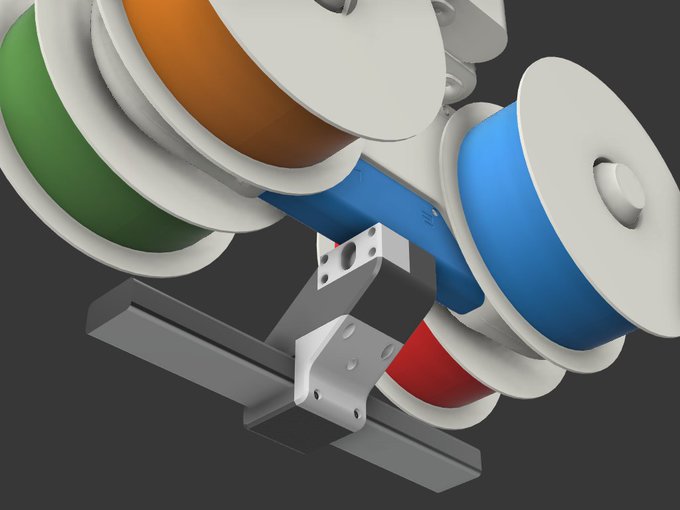

The Bambu Lab spool holder looks good, but it ain't rolln'. Here a mod that Keeps Rollin' Rollin' Rollin' Rollin' - Limp Bizkit

@BambulabGlobal

8

3

51

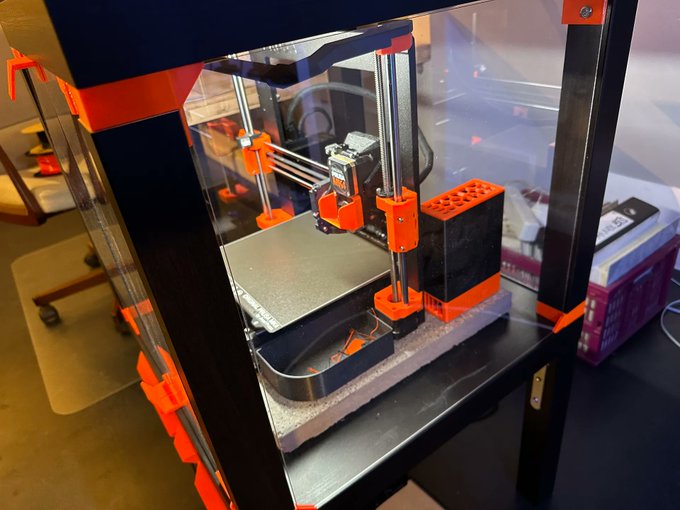

Woohoo. The Prusa Mini+ will be a new addition to my printer family.

@Prusa3D

@josefprusa

would Prusa be introducing pressure advance and input shaping to the Mini+ too?

5

1

50

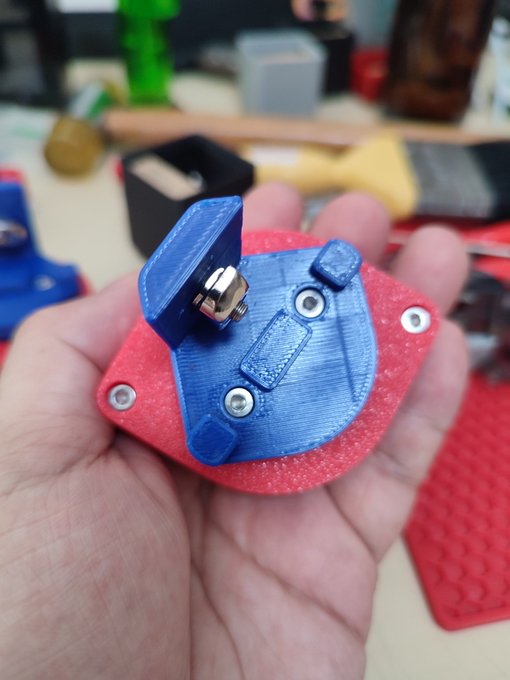

I do not own every printer on the market, and I am fortunate & grateful to have friends and vendors to help me test fit HULA before it gets launched for the community to use. This is

@veetec3d

test fitting on his MK4, and

@fever_soft

for helping me do the same. (1/2)

3

7

45

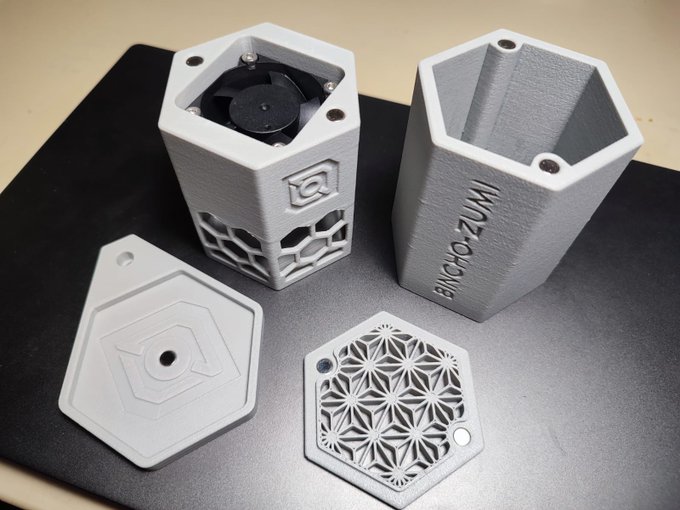

I designed an activated carbon filter for the LDO Trident 300. Meet bincho-zumi, minimalist hexagonal shaped in design with a zen garden-inspired base.

@LDOMOTORSJASON

@VoronDesign

1

8

41

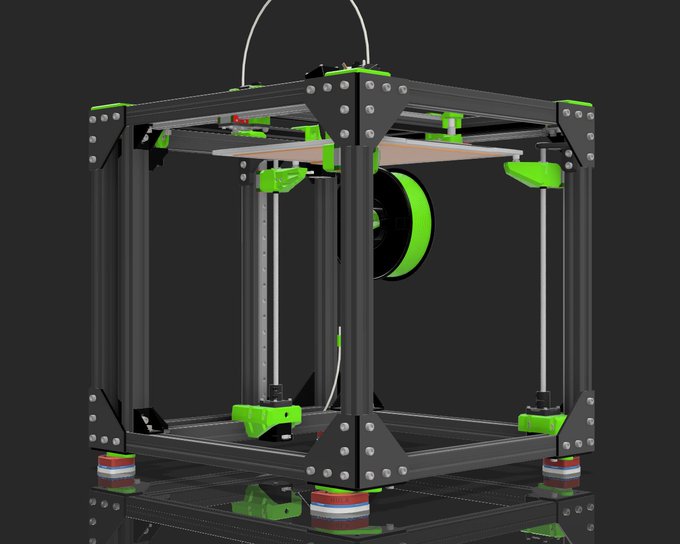

Bear with me, I think I got HULA to go with

@GregoireSaunier

Prusa Bear. HULA HULA

@Paul_GD03

@Prusa3D

#antivibrationfeet

4

5

37

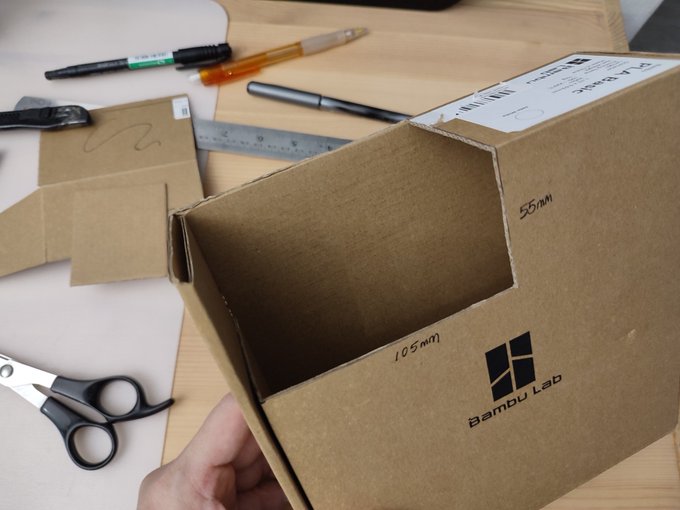

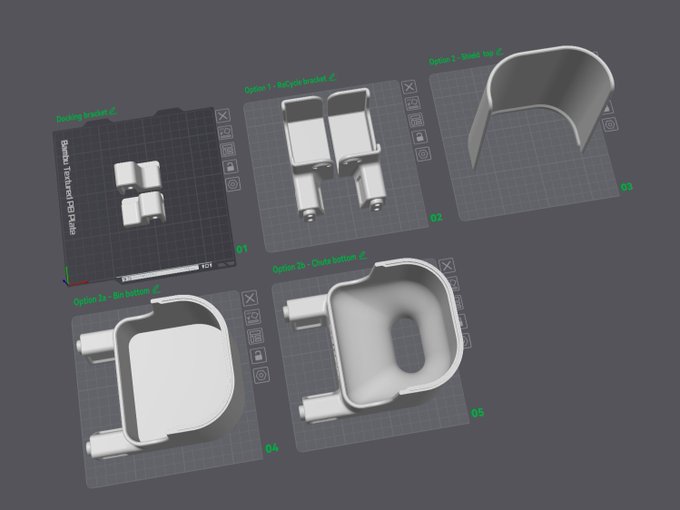

There are many printable poop buckets for Bambu printers. But if you do not print with lots of color changes, you can recycle the cardboard filament box as a poop container.

#Recycle

@BambulabGlobal

@BambulabJapan

4

3

35

Using

@fever_soft

fork version of the BambuLab Studio to calibrate pressure advance for the P1P. A must-have for p1p users.

@BambulabGlobal

@Dr_3DPrint

3

2

34

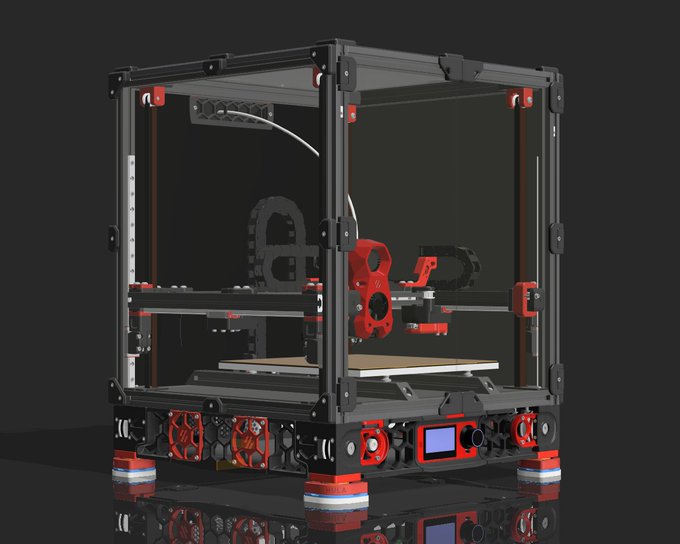

For the next phase - HULA for Voron2.4r2, Trident & Ratrig V-Core3 are undergoing design & testing. Hula for K1 will be the base for these printers.

@voxelpla

now offers HULA and HULA hardware kits for K1.

@Voron_Design

@ratrighardware

3

5

33

Adding mods on the Trident to improve an engineers QOL. These panel latches by richardjm makes removing panels a breeze.

@Voron_Design

@LDOMOTORSJASON

2

2

32

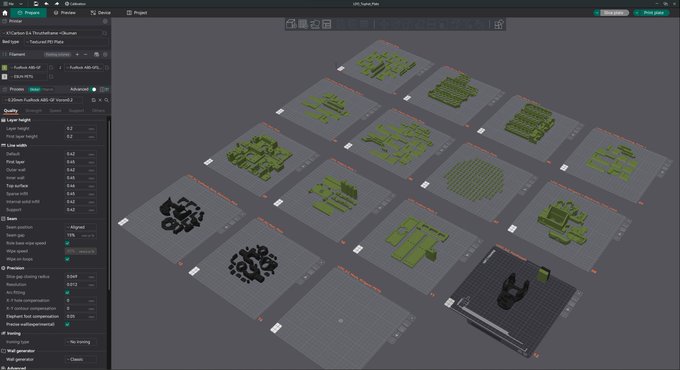

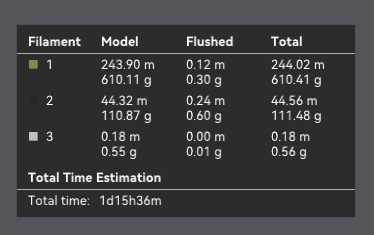

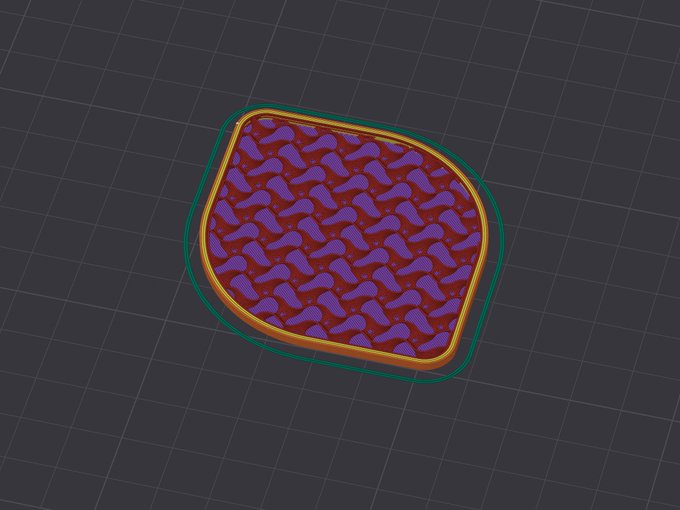

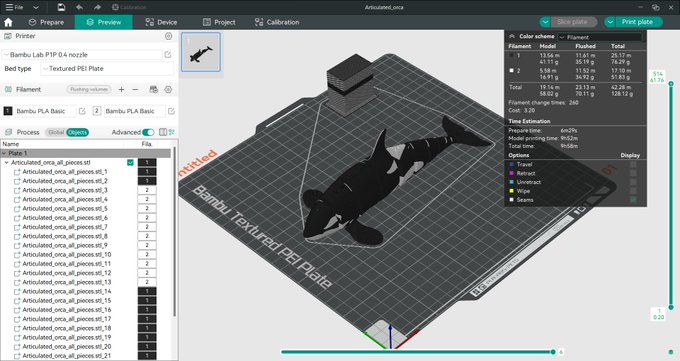

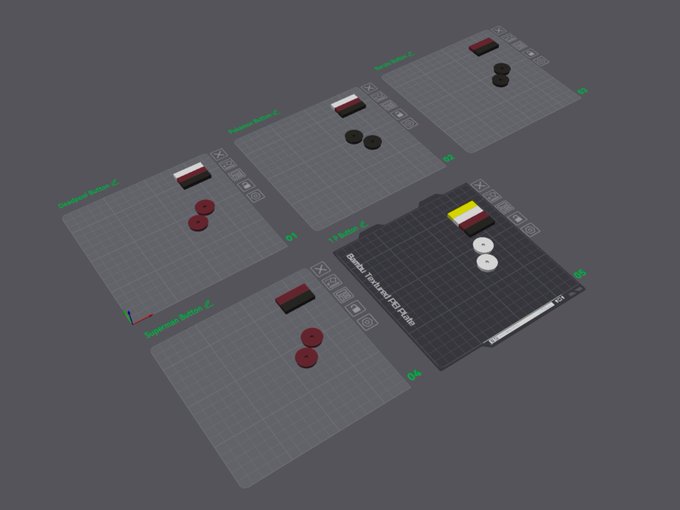

The LDO V0.2 kit is a must-have. Their pre-arranged slicer plates are 🥰. Preparing them using Orcaslicer gives me an overall view and even a rough estimate of the filament required. Perfect combo. Thank you.

@LDOMOTORSJASON

@fever_soft

@Voron_Design

3

1

32

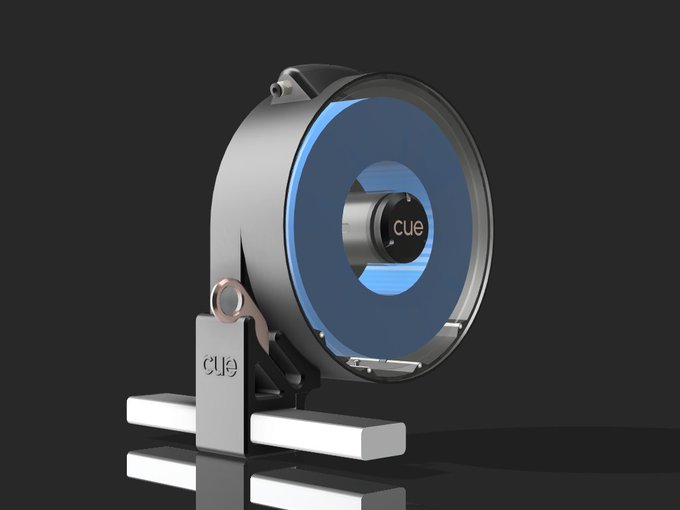

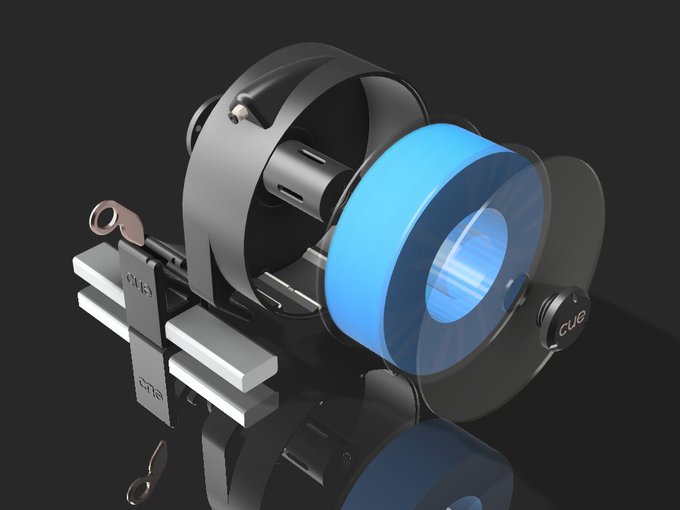

Round and round the spool spins inside CUE. Printing a new lamp shade with a 0.8mm nozzle on the A1.

@BambulabGlobal

4

4

29

FusRock ABS-GF on WhamBam PEX plate for the X1C. When the bed cools to under 40C, the print just releases itself from the plate. No flexing, no scraping. Clean with IPA and it's ready to print again.

#whambam

@BambulabGlobal

@WhamBamSystems

thank you.

3

0

28

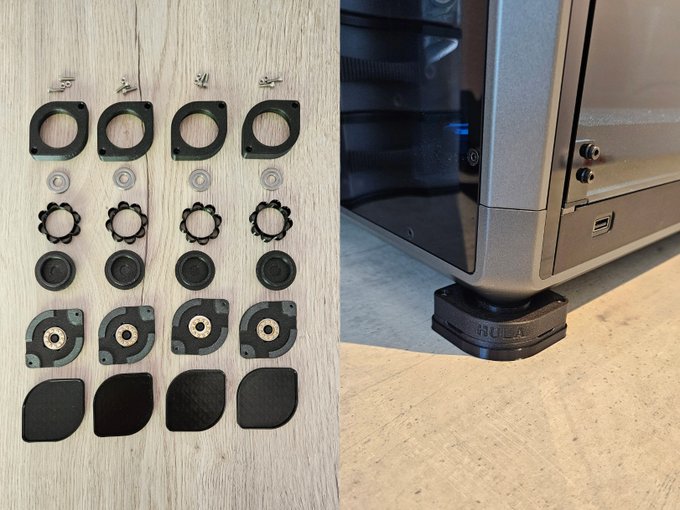

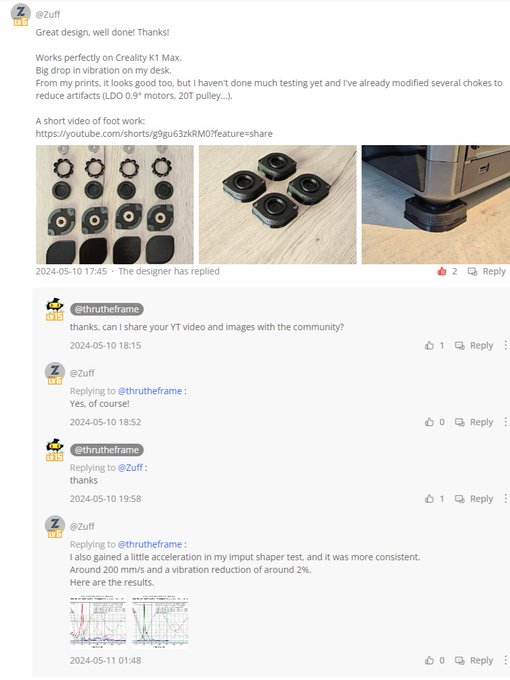

One of the community makers shared his make of HULA for K1 Max. 🥰Thank you Zuff for sharing the test results.

@Creality3dP

Zuff's Youtube video of HULA for K1Max

>>>>>

HULA project page on MW & Printables

0

6

27

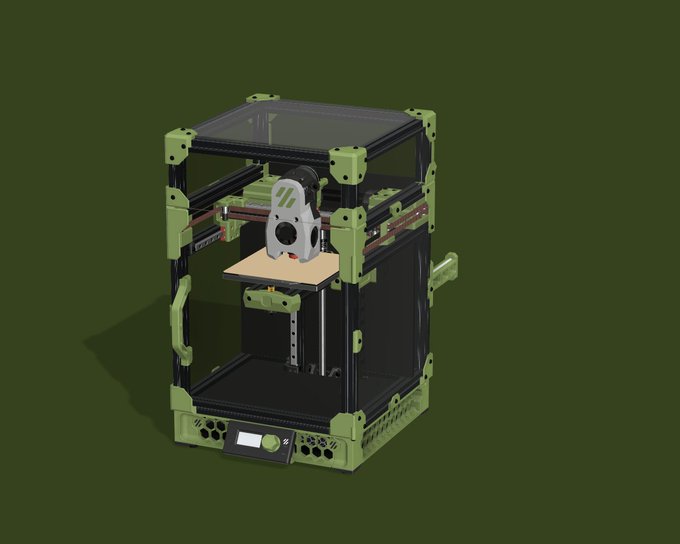

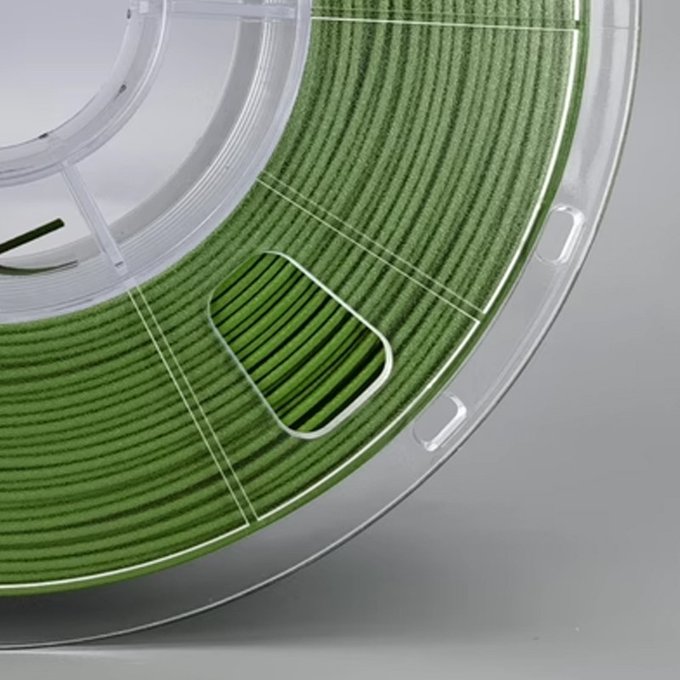

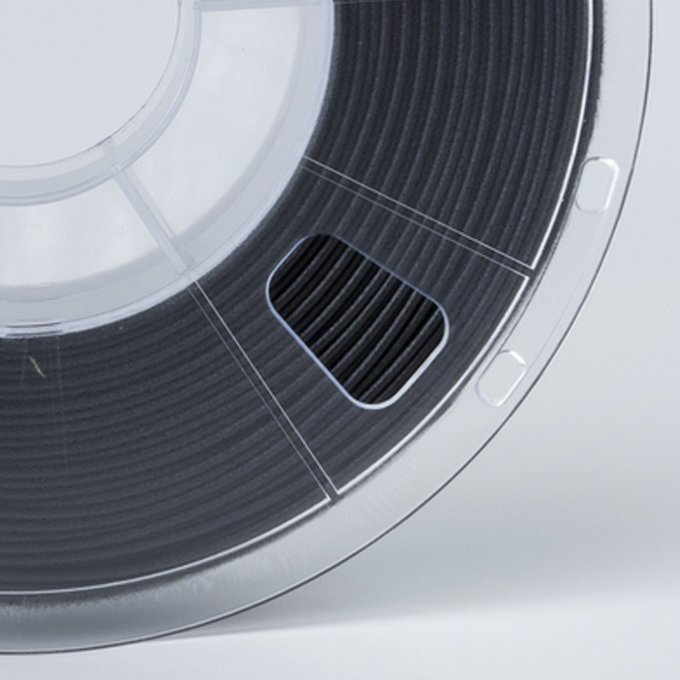

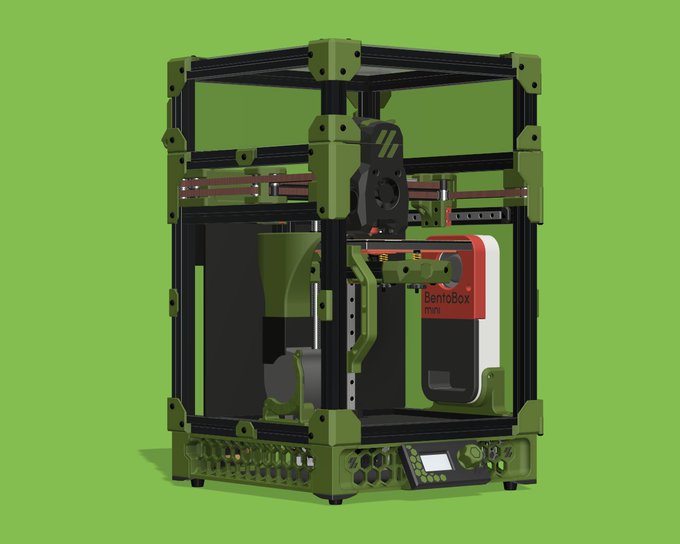

Planning to use FusRock Army Green & Black ABS-GF10% for the upcoming LDO Voron V0.2 build. What do you think?

@Voron_Design

@LDOMOTORSJASON

3

2

26

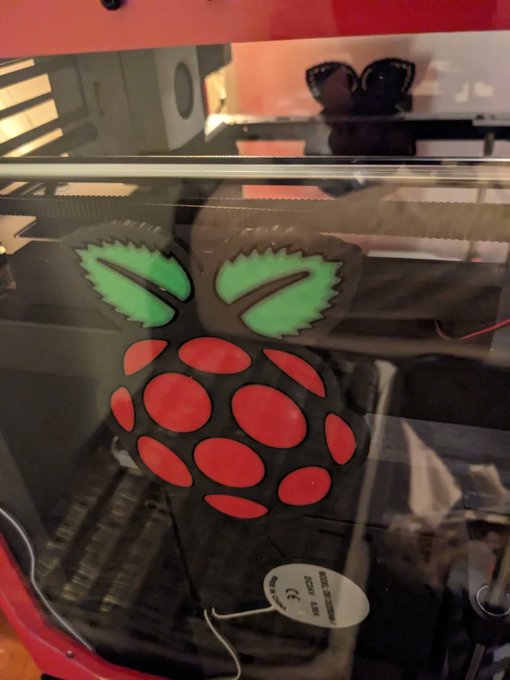

Printing all 3 variants of HULA (Bambu, Creality & Prusa) for the local community in Singapore. Using Bambu Lab Black petg-cf and Prusament Neon Green petg.

#hula

#antivibrationfeet

2

3

26

HULA for Prusa Mk3/4 is now live on Printables. I have prepared the 3mf files in PrusaSlicer to make it easier for makers to print on their Prusa printers. I hope Prusa owners will join in the HULA HULA.

@Prusa3D

@josefprusa

4

7

26

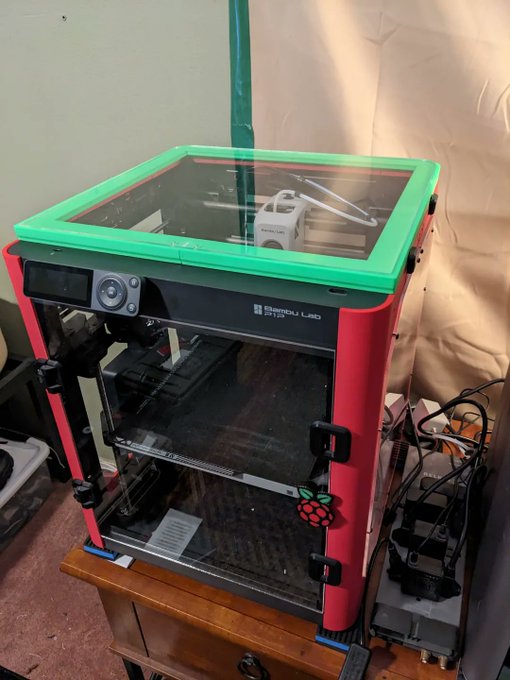

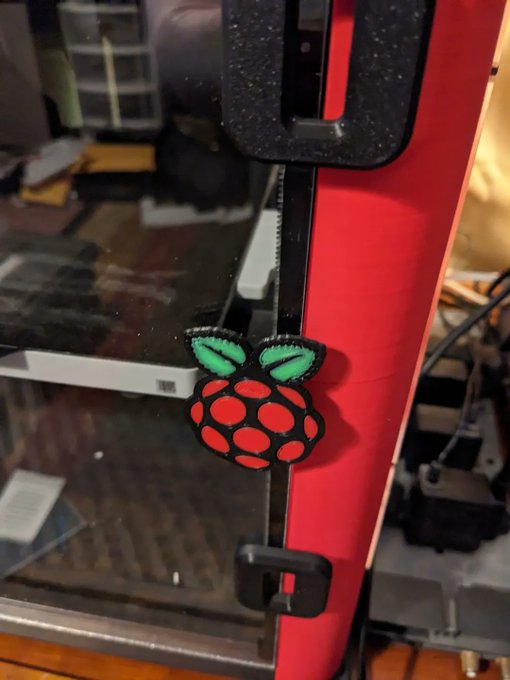

Raspberry ARC by Printer Mcgee. he had shared the make on the ARC project page and has given me the ok to share this awesome personalization of ARC on Facebook groups.

@BambulabGlobal

0

4

24

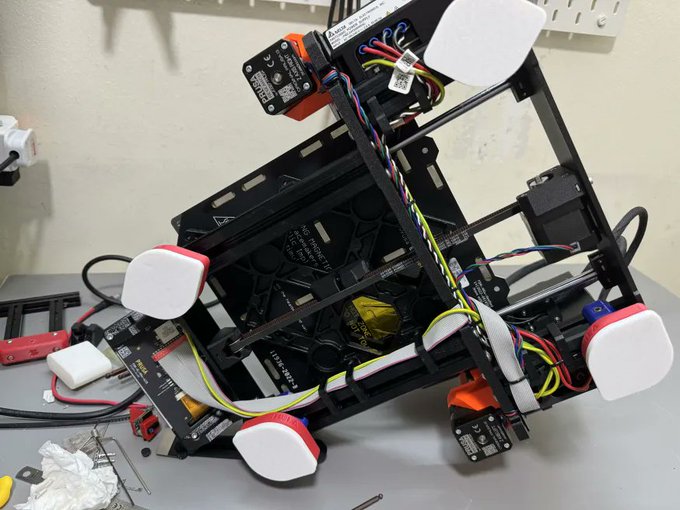

Wahahaha. My LDO Trident 300 is alive. Lots more calibrations are needed. OrcaSlicer works seamlessly, and it basically unified all the different printers I have under one slicer. Thank you

@LDOMOTORSJASON

and

@fever_soft

5

3

24

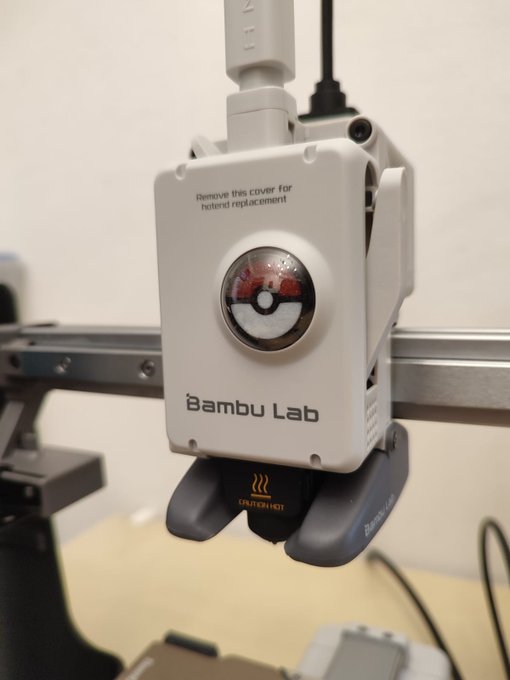

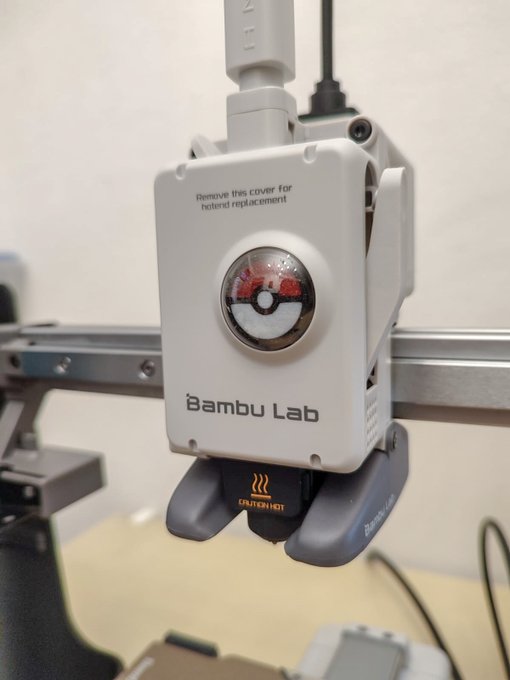

Gotta Catch'em All or Breaking the 4th Wall. Customizing my A1 mini toolhead begins. 😆🤟

@BambulabGlobal

@BambulabJapan

2

5

24

Chute cover and Stiletto poop management system. Will be a hit with the Mrs that the X1C has its own Louboutin. descriptions, stl and 3mf can be d/l from:

@BambulabGlobal

1

1

24

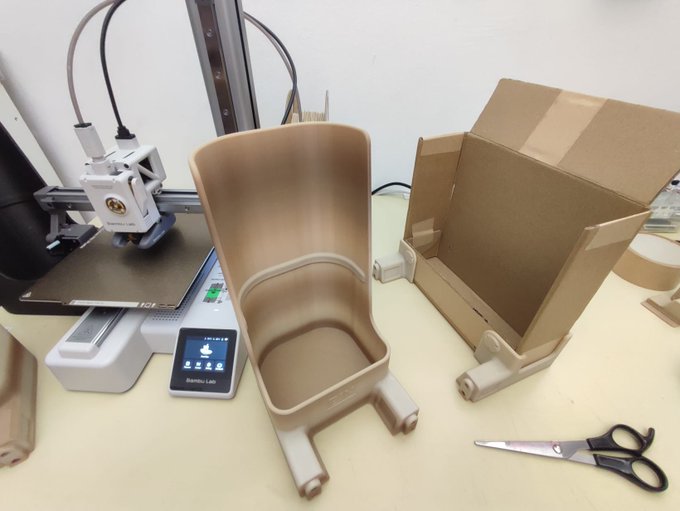

I have designed a set of 3 printable accessories for the

@BambulabGlobal

A1 mini. Poop Management System (PMS), 4-plate stand and a scraper+stylus holder. Preparing the write-up which will be released on Makerworld this weekend. 😄

@BambulabJapan

2

0

22

A friend asked if I could design him a filter system that has low maintenance costs for his Original Prusa Enclosure. He only prints pla and petg, hence I decided to design it as a single-pass filter system with HEPA and refillable activated carbon filters.

@Prusa3D

.

2

3

22

I have designed GRIP, the A1 AMS lite top mount. While there is an official BL version, Mine is more secure as my bracket is screw lock, and easier to print. Its also slimmer 🤣(shameless promotion)

@BambulabGlobal

@BambulabJapan

2

2

20

BentoBox is not just for Bambu Lab printers. I shared the step file of the fan duct base to encourage remixes, and the community did not disappoint. Mounting for Creality K1, Qidi X+3, Lack Enclosure with the Mk4 and even Prusa XL. 🤟🥳

@Creality3dP

@QIDI_3dprinter

@Prusa3D

(1/2)

2

3

16

This is definitely an awesome must-have mod for Bambu Lab's AMS. The ptfe adapter was designed and shared by

@Ktothestank

@BambulabGlobal

2

1

20

PETG-GF (glass fiber) on Wham Bam PEX plate (hair spray used). Printed on the P1P with an ARC enclosure.

@WhamBamSystems

@BambulabGlobal

2

3

19

Read the manual twice, sort/label the profiles, bag the printed parts accordingly. But I build the tophat first. Why? Because it's my warm-up, getting the hang of things before i start the main. Wish me luck.

@LDOMOTORSJASON

the profiles are very well cut and made. Love it.

1

1

19

The

@BambulabGlobal

A1 mini Poop Management System is now available for download on Printables. Mine was printed in Gurum Brown PLA from which blends with the cardboard spool box perfectly.

5

7

19

HULA -> フラ. To the Bambu Lab Japanese Community, Happy Holidays

@BambulabJapan

@BambulabGlobal

. You can download the フラ top cover from MakerWorld's HULA project.

1

4

19

🥳🥰Happy to see user duo.sly using my printable mods for his new

@BambulabGlobal

A1 mini. The Poop Bin, Stable Build Plate Stand, Stylus+Scraper Holder, and the Customizable Window Button using Switch Controller thumb cover. MakerWorld links are in the comments.

2

2

19

"....friends do not let friends poop everywhere..." PoobyMaster

@UncleJessy4Real

@BambulabGlobal

thank you

@davemakesstuff_

for the awesome design.

2

4

19

Redesigned the base of BentoBoxV2 to be used on the Voron Trident. Fit both 250 and 300. Wire it to one of the pwm fan ports and bam you have a HEPA + activated carbon filter.

@LDOMOTORSJASON

@Voron_Design

5

2

18

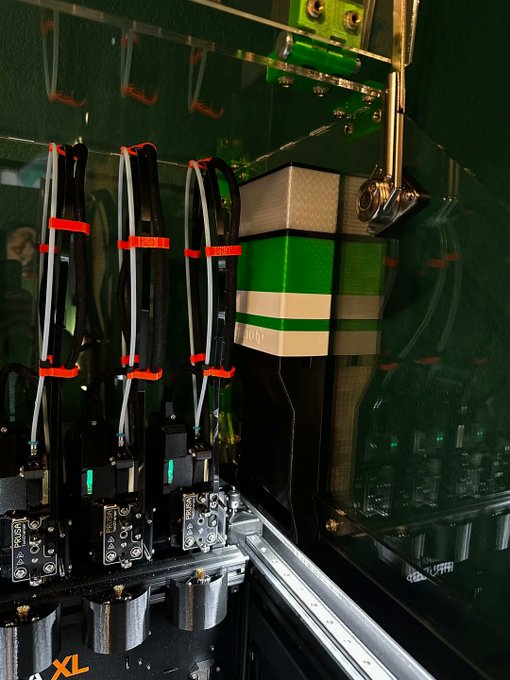

The Voron Trident 300 build is complete. I like the clean and simple look. Currently print speed is average, limited by the flow of a ST Dragon+ HS nozzle. Till the HF heatbreak and CHT arrive. Up next LDO's Voron 0.2.

@LDOMOTORSJASON

thank you very much.

2

1

17

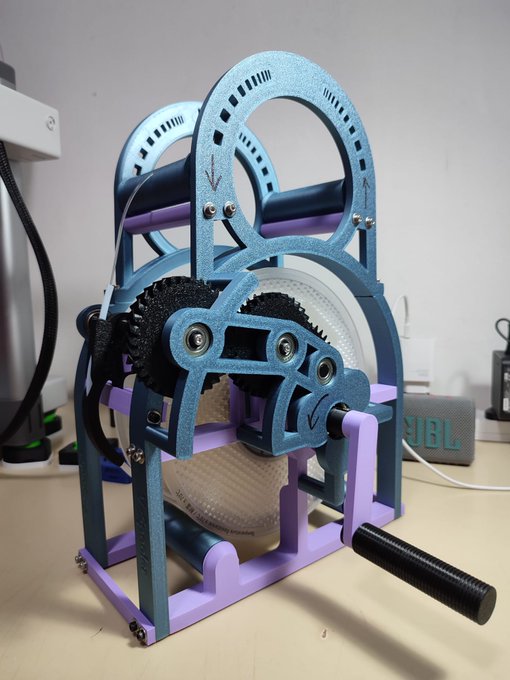

I tried several re-spoolers. V-spooler from

@FyrbyAdditive

is the one I like best, & it's easy to store away when not in use. It requires 608 bearings and an array of fasteners. I would recommend getting the hardware kit from (sharing and not an afflink)

3

1

18

Personally I enjoy using the A1 mini to push out prototype parts fast. In this short vid, I m using

@BambulabGlobal

petg-cf in a passive drybox.

1

1

17

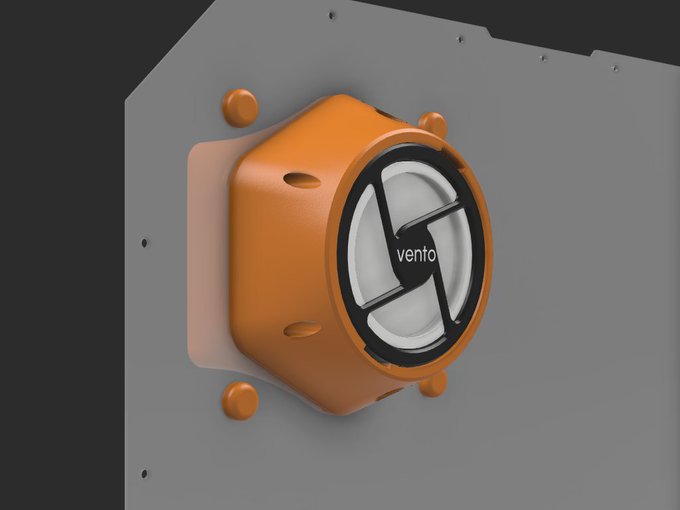

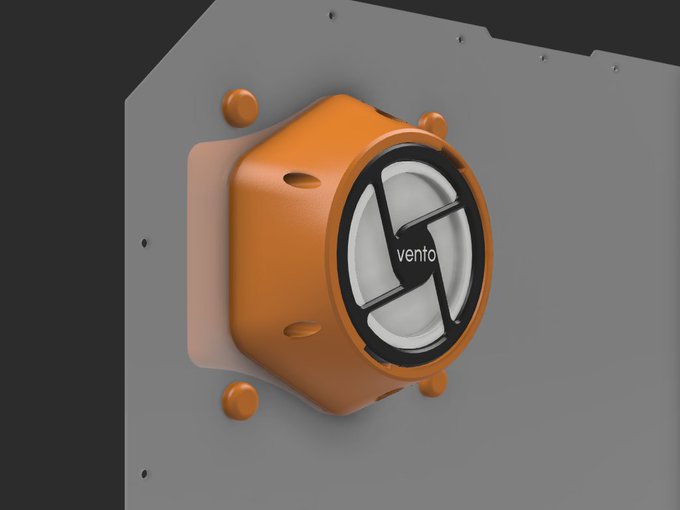

Good news.

@veetec3d

the EU vendor for BentoBox has started selling fully built Vento (a carbon + HEPA air filter system) for the Original Prusa Enclosure.

@Prusa3D

#originalprusaenclosure

#OPE

0

2

15

Having worked with rails from crap I bought off Aliexpress to buttery-smooth Misumi. These rails from LDO are lovely. Only needed some minor cleaning, a few drops of Singer oil and they are good to go.

@LDOMOTORSJASON

thanks

0

2

16

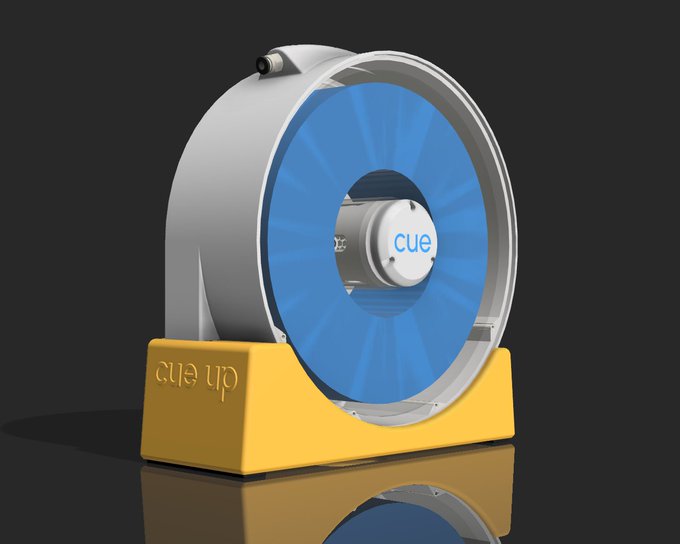

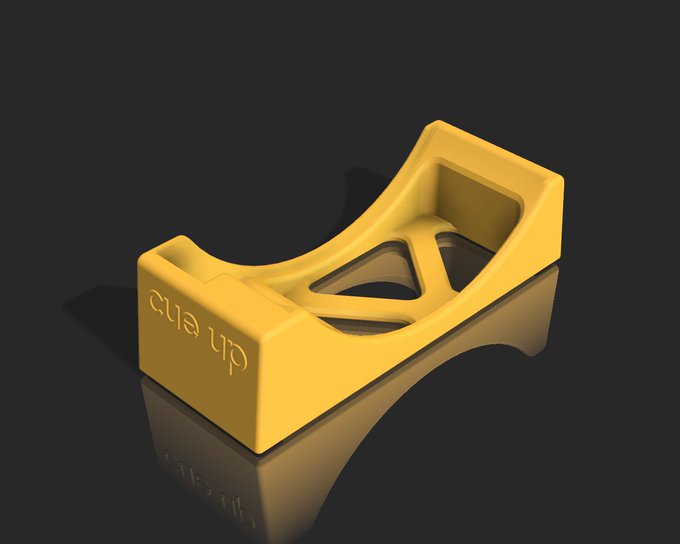

Expanding the CUE ecosystem, I have designed a tabletop holder called "cue up" For smaller printers like the

@BambulabGlobal

A1 mini and

@Prusa

mini. No more worries about petg soaking up moisture from the air.

0

1

14

been printing with

@BambulabGlobal

TPU 95A HF on the A1 mini. With the K value dialed in and some minor changes to the stock setting, the finish is really good with almost no stringing. Hint😉I used scarf seam on OrcaSlicer.

@fever_soft

0

0

16

I decided to take a week off 3D printing, and these came in for the V0.2 😅 The force is strong, must resist.

@247_printing

2

1

16

Thank you

@ModBotArmy

for showcasing the

@BambulabGlobal

A1 mini poop bin on your live stream last evening. I am preparing the instruction guide and will release the files on Friday.

@BambulabJapan

1

3

16

Prototyping consumes lots of filament. This is only 1/3 of the of the fail print for CUE which uses more than 4 spools of PLA. I would like to thank

@BambulabGlobal

for the continuous support so I can focus on designing stuff for the community. (1/2)

2

2

16

Printed the Giant Spiralized Sphere by

@davemakesstuff_

with the P1P using Bambulab white pla. Resized to 80% hang it over the IKEA TERTIAL lamp on my workbench. I get great diffused light and me wife was impressed with how nice it looked.

1

4

14

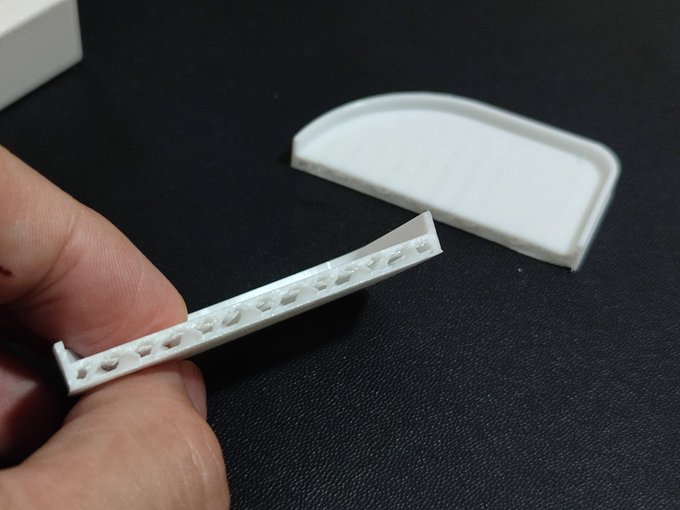

Slow but steadily printing the parts for the LDO Trident 300. Using FusRock ABS-GF 10%. It's a brittle filament but the Bambulab AMS was able to work with it.

@LDOMOTORSJASON

@BambulabGlobal

0

1

14

The

@BambulabGlobal

A1 meets its mini-me. What are the first few things I am going to print on it? Definitely, mods and accessories I designed. 😆

#A1combo

#BambuLab

#BambuLabA1

0

1

14

Test printed the Voron cube on Bambu Lab X1C to tune the printing profile and check dimension accuracy. FusRock ABS-GF 10%. Looking good and almost ready to start churning out the part for LDO Trident 300

@LDOMOTORSJASON

@BambulabGlobal

#Trident

#Voron

0

2

14

I don't just design things for Bambu Lab printers. I also designed the Vento, a low-cost air filter system for Original Prusa Enclosure and other DIY enclosures. 😅

@Prusa3D

1

1

14

Running vibration comp calibration on the A1 with 4 spools of assorted weight, making the GRIP CG off-centered. The spool wobbles at very low frequency, but stabled down after. Did the printer wobble like jelly? Nope. The rattling sound was from the tool beside

@BambulabGlobal

1

1

14

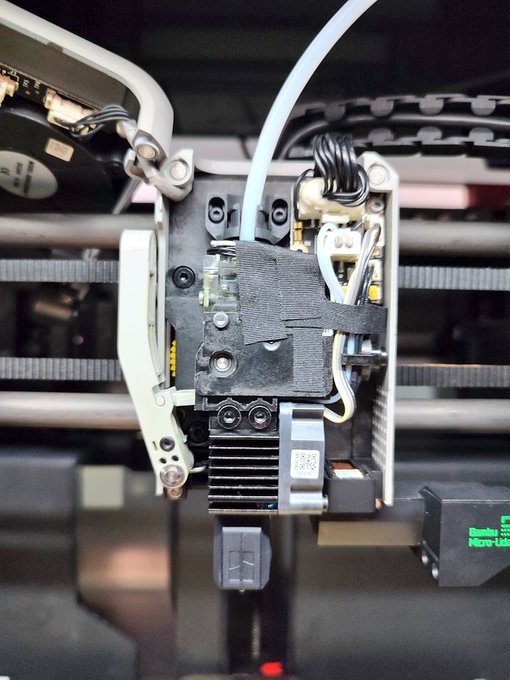

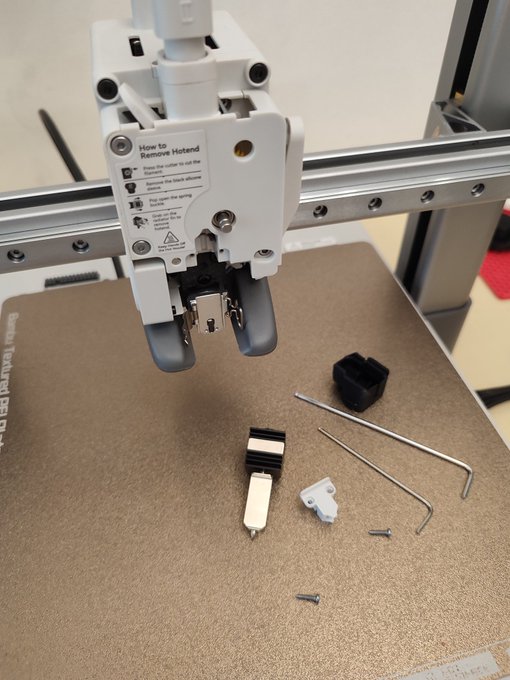

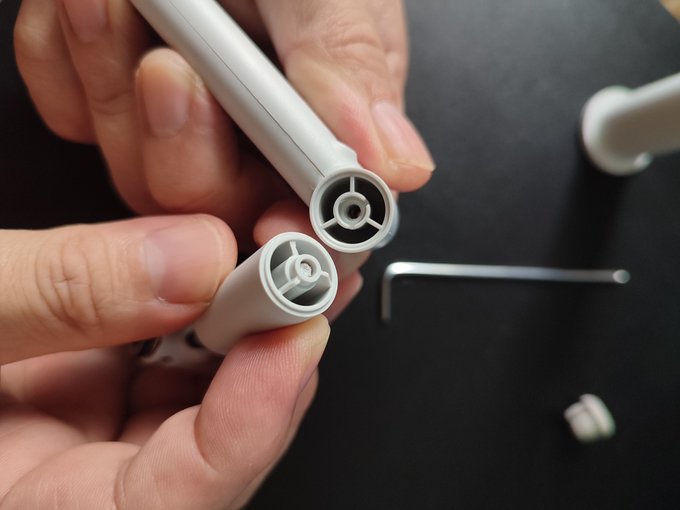

My first extruder clog on the A1. I hope the quick clean up can solve the issue.

@BambulabGlobal

#A1

2

1

13

I was hoping to launch cue on 1/1. Sadly, myself & wifey got COVID. Hence all 3dp projects are put on the hold till recovery. Below is a short vid of the desiccant container being installed into cue.

@BambulabGlobal

@BambulabJapan

#A1

(1/2)

2

0

13

7hrs of measuring, loosening, tightening & repeat to get the X gantry bind-free and squared. 内伤吐血。Luckily I do not stream, viewers will 吐血 too. 😂

@Voron_Design

@LDOMOTORSJASON

2

0

13

Fun fact: Do you know that the A1 single spool holder was designed to be ambidextrous. It can be set up to have the filament loaded from the left or right.

@BambulabGlobal

@joeltelling

@247_printing

@UncleJessy4Real

0

1

13

Living in a humid country, I have difficulty printing petg without a drybox. Met cue. A single spool passive dry box for the Bambu Lab A1 printer. Testing has been ongoing and I hope to release it on new year day 2024.

@BambulabGlobal

@BambulabJapan

0

1

13

@BambulabGlobal

is launching Make Your Sign on their MakerWorld this Thur 2100hr GMT+8, a smart way to bring functional CAD to the masses. I got the chance to be a beta tester and the first thing I did was to create a very smart sign.

@loyalmoses

1

1

13

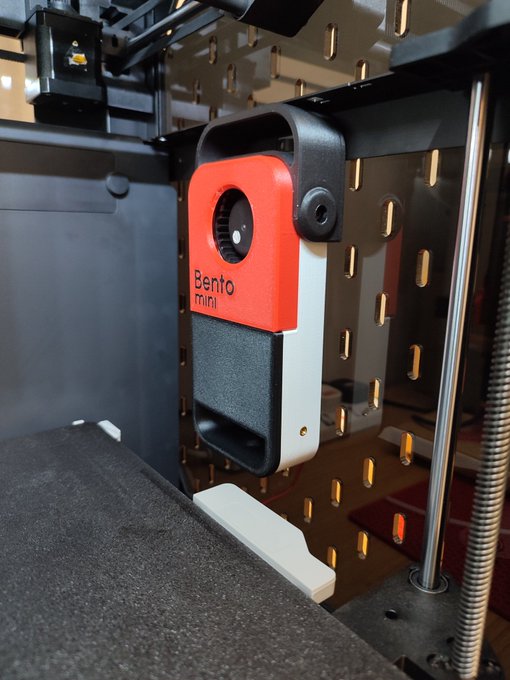

Thank you

@ModBotArmy

for showcasing my Bento Mini and Guile RSCS for Voron V0.2 with

@phaetus3D

pet-cf filament. The prints were perfect. 🥰

0

2

13