BISHEN CNC machining metal&plastic parts

@shenBi13370

Followers

1

Following

3

Media

41

Statuses

125

High precision CNC parts supplier! AS9001/ISO13458/ISO9001 certified aeroplane|medical|robotic| others WhatsApp/wechat:18218413685

shenzhen ,china

Joined December 2024

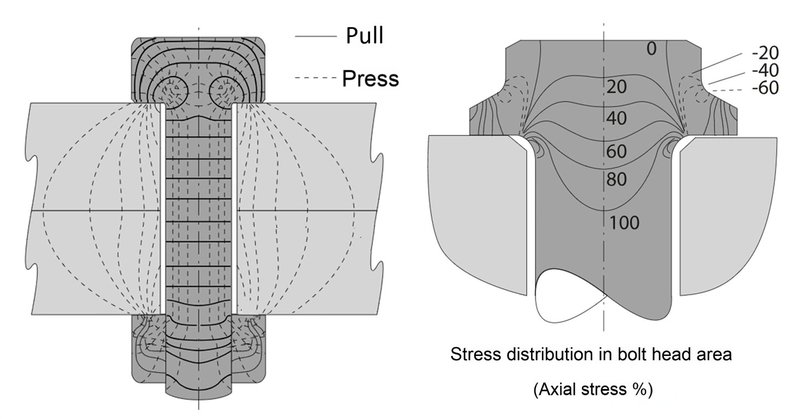

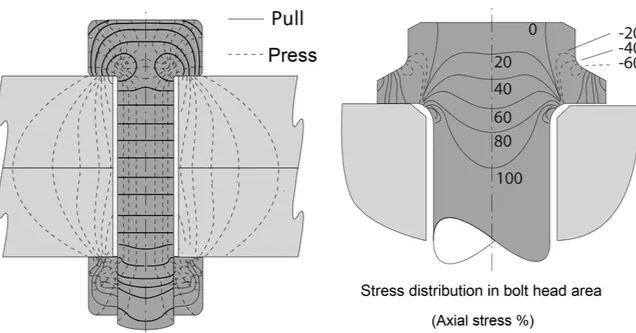

Learn the top bolt failure points: thread root (65%), thread-to-rod transition (20%), and head-to-screw junction (15%)#FastenerFailure #FatigueAnalysis .#PrecisionManufacturing.via @https://www.bishenprecision.com.

bishenprecision.com

The most vulnerable position and cause of bolt failure

0

0

0

Aerospace aluminum-based silicon carbide threaded hole processing solutions - news via @https://www.bishenprecision.com.

bishenprecision.com

Aerospace aluminum-based silicon carbide threaded hole processing solutions

0

0

0

Our latest breakthrough uses ultrasonic vibes + super-durable PCD tools to nail micro-holes (Ø0.2mm deep!).#AerospaceTech #compositematerials #PrecisionDrilling #ultrasonicmachining via @LinkedIn.

linkedin.com

As a precision machining specialist focused on high-performance materials for the aerospace industry, I've seen firsthand how advanced composites like Carbon Fiber Reinforced Silicon Carbide (Cf/SiC)...

0

0

0

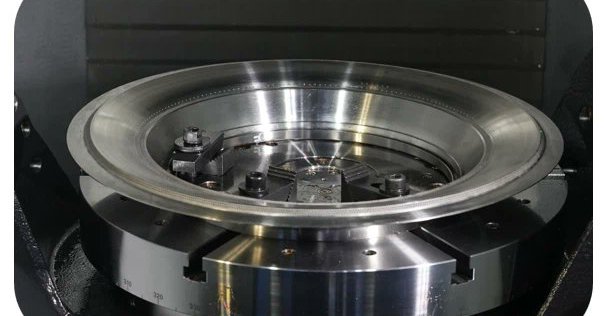

Aluminum–SiC composite brake discs: lightweight, wear resistant, and CNC machined to precision. #CNCmachining #wearresistance #brakedisc #precisionengineering #SiCcomposite #custommachining #metalworking #highprecision via @https://www.bishenprecision.com.

bishenprecision.com

Aluminum-based silicon carbide brake disc precision drilling solution

0

0

0

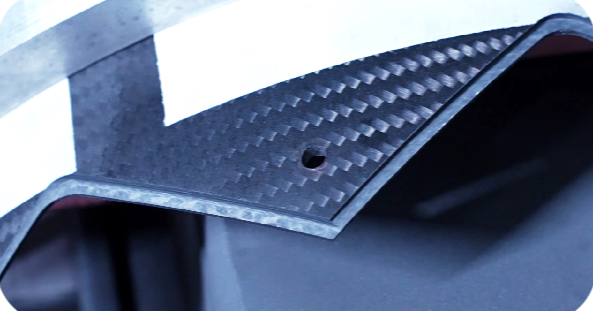

Struggling with CFRP in aerospace? Discover how ultrasonic machining deliver smoother, more precise cuts, extend tool life, and reduce costs. #AerospaceManufacturing #CFRP #UltrasonicTechnology #CompositeMaterials #AerospaceEngineering via @LinkedIn.

linkedin.com

Processed Product Material: Carbon Fiber Reinforced Polymer (CFRP) Processing Features: Drilling and Contour Milling Challenges in Aerospace Manufacturing Carbon Fiber Reinforced Polymer (CFRP) is...

0

0

0

Smooth 6 mm carbon fiber cutting — no chipping, no burrs, faster output. Powered by ultrasonic CNC 5-axis tech. #CNCmachining #carbonfiber #ultrasoniccutting #precisionmachining via @LinkedIn.

linkedin.com

Processed Product Material: Carbon fiber preform Processing Features: Cutting of both inner and outer contours (Thickness: 6mm) Project Background Carbon fiber preforms are commonly used in industr...

0

0

0

Ultrasonic-assisted CNC drilling in GH4169 alloy slashes hole time (53 → 10 min), boosts finish, and extends tool life. #CNCmachining #GH4169 #precisiondrilling #ultrasonicmachining #aerospaceparts #highprecision #metalworking

bishenprecision.com

Solution to the problem of drilling and reaming holes in GH4169 high-temperature alloy for aircraft engines

0

0

0

Shot peening boosts fatigue life—even on rough surfaces. #CNCmachining #shotpeening #fatiguestrength #machiningservices #custommachining #cnccomponents #metalparts #surfaceengineering #cncmanufacturing

bishenprecision.com

Why Shot Peening Improves Fatigue Strength Despite Rougher Surface

0

0

0

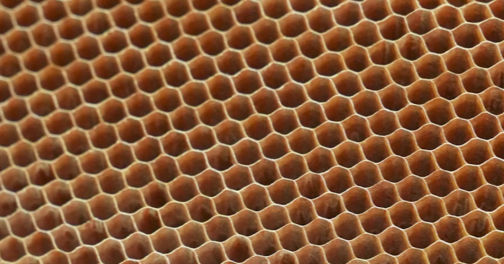

Clean, burr-free aramid honeycomb cuts at <18°?.We made it happen—with ultrasonic CNC and zero tool breakage. #CNCmachining #UltrasonicMachining #CompositeMachining #BurrFree #5AxisMachining #AramidHoneycomb #HighPrecision #ToolLife #AdvancedCNC

linkedin.com

Aramid paper honeycomb is widely used in aerospace and high-performance structural applications for its lightweight strength and excellent energy absorption. However, machining this delicate and...

0

0

0

Thread roots are where most bolt failures start. Know why. #CNCmachining #failureanalysis #fasteners #machiningservices #precisioncomponents #custommachining #tighttolerance #threading #cncparts via @LinkedIn.

linkedin.com

Bolts are the most commonly used fasteners, and they encounter the most failures. For bolts, do you know where the most common failure location is? As shown in the figure below, there are actually...

0

0

0

CNC turning K4169 bearing sleeves—no chatter, high stability. #CNCmachining #precisionturning #K4169 #aerospaceparts #custommachining #cnclathe #metalprocessing #cncservices via @LinkedIn.

linkedin.com

Core Processing Challenges Material properties: cast nickel-based high-temperature alloy K4169 (HRC46 hardness) Process requirements: internal and external turning (aircraft bearing seat assembly...

0

0

0

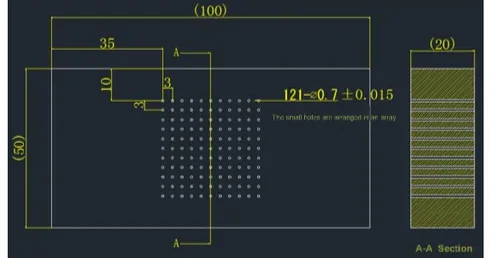

Micro-hole CNC on 6061 Aluminum—clean, accurate, burr-free. #CNCmachining #microhole #aluminumparts #precisionmachining #cncdrilling #custommachining #5axismachining #metalprocessing #machinedcomponents via @LinkedIn.

linkedin.com

Processing Case: Aluminum Alloy 6061 Spray Plate Depth-Diameter Ratio Micro-Hole Processing A chip equipment manufacturer needs to mass-produce aluminum alloy spray plates for cooling systems in chip...

0

0

0

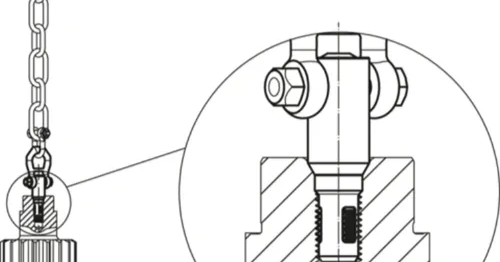

CNC precision for threaded center holes—small feature, big impact. #CNCmachining #threading #cncmilling #precisionmachining #metalworking #5axismachining #customparts #machiningservices #machinedcomponents via @LinkedIn.

linkedin.com

A threaded center hole, also known as the "C-type center hole" in our country or the "D-type center hole" in the DIN standard, is commonly seen in many mechanical structures and drawings. When to...

0

0

0

5-axis ultrasonic CNC machining for precise air film holes in alloy blades. #CNCmachining #5axismachining #ultrasonicmachining #turbineblade #airfilmhole #precisionmachining #metalworking #machiningservices #alloymachining via @LinkedIn.

linkedin.com

Processed Products Material: Nickel-based high-temperature alloy Processing features: φ0.5/0.

0

0

0

Precision 5-axis CNC machining for glass ceramic dental crowns. #CNCmachining #5axismachining #dentalcrowns #glassceramic #cncmilling #precisionmachining #metalworking #highprecision #machiningservices

bishenprecision.com

Five-axis machining technology for precision glass-ceramic crowns solves the problem of high edge collapse in dental accessories industry

0

0

0

Precision CNC machining for aerospace combustion chamber alloy parts. #CNCmachining #aerospaceparts #5axismachining #alloymachining #cncmilling #enginecomponents #metalworking #precisionengineering #machiningservices #highprecision

bishenprecision.com

High-temperature alloy aircraft engine combustion chamber oblique hole processing solution - ultrasonic five-axis linkage technology without remelting layer

0

0

0

MALO bridges in TC4 titanium—thin walls, tight tolerances, CNC precision. #CNCmachining #titaniummachining #medicalparts #TC4alloy #5axismachining #cncmilling #dentalimplants #precisionengineering #machiningservices

bishenprecision.com

High-efficiency precision machining solution for titanium alloy TC4 Malone Bridge - ultrasonic five-axis burr-free milling technology

0

0

0

Thin-wall titanium parts demand true CNC precision—strength, stability, and control. #CNCmachining #thinwallmachining #titaniummachining #cncmilling #5axismachining #highprecision #metalworking #machiningservices #aerospaceparts

bishenprecision.com

Solutions to the Problem of Thin-wall Processing of Titanium Alloys: How Five-axis Ultrasonic Technology Achieves Precision Manufacturing

0

0

0

Precision machining of titanium-aluminum integral blades for aerospace applications. #CNCmachining #5axismachining #titaniummachining #aerospaceparts #integralblade #highprecision #cncmilling #metalworking #machiningservices

bishenprecision.com

Breakthrough in machining titanium-aluminum alloy integral blade rings for aircraft engines: How five-axis ultrasonic technology can improve service life

0

0

0

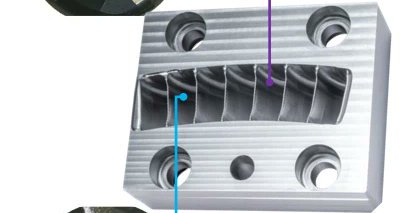

5-axis CNC machining—ideal for precision impellers. #CNCmachining #5axismachining #impeller #cncmilling #precisionmachining #metalworking #machiningservices #highprecision #complexparts #engineering

0

0

0