CNC Robotics

@cnc_robotics

Followers

3K

Following

2K

Media

587

Statuses

2K

Leading robotic integrator specialising in advanced machining and large format additive manufacturing solutions. +44(0)151 523 8009

Unit 3 Mersey Reach, Liverpool

Joined April 2013

Our client, Total Machining Solutions, completed their first print using our Kuka CEAD 3D printing system. Taking just over 28 hours, at a size of 2600mm x 650mm x 450mm made from C250CF Dahltram. See the finished mould below👇

3

7

29

Discover the KUKA_CEAD system and CEAD 3D printing technology here: https://t.co/HVPtr9bFTJ

cncrobotics.co.uk

CNC Robotics offer the newest CEAD technology with robot based, large format 3D Printing Systems for the composites industry.

0

0

1

This direct tool will be used in an autoclave and is for one of their valued Aerospace clients. Once printing is completed it is then transferred to a CNC machine for a final machining cut to gain the finish and accuracy needed for this tolerance critical project.

1

0

3

If you manufacture with one of these materials and would like a cheaper alternative to traditional manufacturing systems, get in touch 👇 max.barnett@cncrobotics.co.uk #cnc #machining #manufacturing #robotics #automation #milling #trimming

0

0

1

Other materials this system is capable of working on include: - Tooling/Modelling Board - Low Density Metals - Thermoplastics - Carbon Fibre - Polystyrene - Glass Fibre - Plastic - Wood - Stone

1

0

1

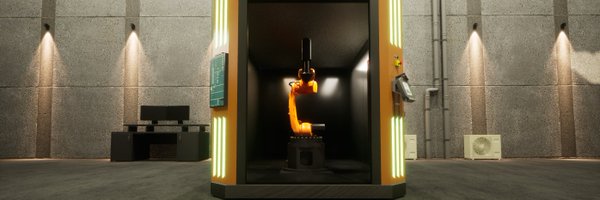

With a 210kg payload KUKA robot, 2700mm reach, rotary table and a 3D workspace, that includes a 10-station tool changer, Rojac have automatic, flexible tooling selection for specific material removal.

1

0

0

7-Axis Robotic System - What materials can you machine? This CNC Robotics Ltd milling system for Rojac Urethane is primarily used for the machining of prototype seat foams directly from CAD.

2

3

5

More information: https://t.co/d9qxXgwNqo

#composites #manufacturing #industry #robotics #3dprinting #automation #cnc #milling #sustainability

0

0

1

Send an email through to: max.barnett@cncrobotics.co.uk CNC Robotics order book is open for the Paste Pro, an integration of the 2KM extruder, KUKA robot and Sika material. We can talk through material properties, print strategies, costs and machine trial possibilities.

1

0

1

And would like to streamline the process to this: Prepare material tank 3D print to the near net shape of the final mold or prototype Swap the print head on the end of the robot for a router, apply finishing and machining processes in one continuous workflow

1

0

0

Machine down to the final shape of the mold or prototype, wasting ~80% of material in the process Apply additional finishing processes to achieve the desired surface quality and dimensional accuracy Waste management of large volume of leftover material

1

0

0

Does your current process look something like this: Procure multiple blocks of tooling board needed for creating a mold or prototype Bond blocks of tooling board together to form a larger block big enough to encompass the entire mold or prototype

1

0

0

Composites Manufacturers looking to improve their prototyping and tooling processes read this 👇

2

4

3

As official UK resellers of CEAD Group technology, CNC Robotics Ltd offer the Flexbot solution as well as extruder integrations, maintenance and training. Contact us for more information 👉

ceadgroup.com

Contact us Looking for more information or a quotation? We are happy to help you further. Please contact us via one of the contact options below or fill in the contact form. We will get back to you...

1

0

1

When the mould is no longer needed, the material can be broken down into pellets to be reused. This process not only resulted in a lightweight mould but also demonstrates a sustainable production method with fast lead times.

1

0

0

Using the CEAD Flexbot, Forze was able to print a vacuum infusion mould of 2m x 2m, 3D printed with Dalthram resins from Airtech Advanced Material Group. Additionally, the robot is equipped with an end of arm toolchange for automatic transition from 3D printing to milling.

1

0

0

3D Printing a Large, Sustainable Mould for the Automotive Industry 🏎 The collaboration between CEAD Group and Forze Hydrogen Racing highlights the potential of large format additive manufacturing in the automotive industry.

4

4

14

We also offer a #KUKA smartPAD exchange/repair service on KRC4. This service is an exchange repair to avoid downtime on systems. For more information, visit our website:

1

0

1