SIMPSON

@Simpson_Group

Followers

696

Following

994

Media

1K

Statuses

1K

For over 110 years Simpson has been an innovator of industrial process technologies for the foundry and process industries.

Naperville, IL

Joined May 2015

Simpson’s Cory Ashburn, Tom Arenholz & Bruce Dienst joined the AFS 4M Committee meeting to share insights and drive advancements in metalcasting. Working together to shape tomorrow. #AFS #ShapingIndustry

0

0

0

Simpson doesn’t just sell to foundries—we buy from them too!. We recently saw a Model #1F Mix-Muller® bedplate mold just before pouring—soon headed into machines for other foundries. Shaping Industry, Together.

0

0

2

🔥 Foundry heat is no joke. Stay safe:.💧 Hydrate often.🧢 Wear breathable layers.⏱️ Take cool-down breaks.🧊 Use cooling gear.🧠 Know heat stress signs.Keep the pour hot, and your team cool. 💪 #FoundrySafety #HeatSafety #StayCoolStaySafe

0

0

1

🔧 Just coming out of shutdown? Now’s the time to replenish spare parts. ✅ Prevent delays.✅ Stay production-ready.✅ Keep equipment running strong. We’re here to help—contact us today. #SpareParts #FoundrySupport #MinimizeDowntime

0

0

0

Global reach. Local support. Proven performance. 🌍.Simpson delivers fast response, tailored solutions, and reliable service—wherever your foundry operates. #BuiltForFoundries #SimpsonSolutions

0

0

1

🎆 Happy 4th of July from Simpson!.We're proud to support foundries worldwide—and celebrate our U.S. roots from our Global Tech Center in Illinois. Thanks to our global community for your partnership!. 🇺🇸 Our U.S. Tech Center & warehouse will be closed July 3–4. #Happy4thofJuly

0

0

2

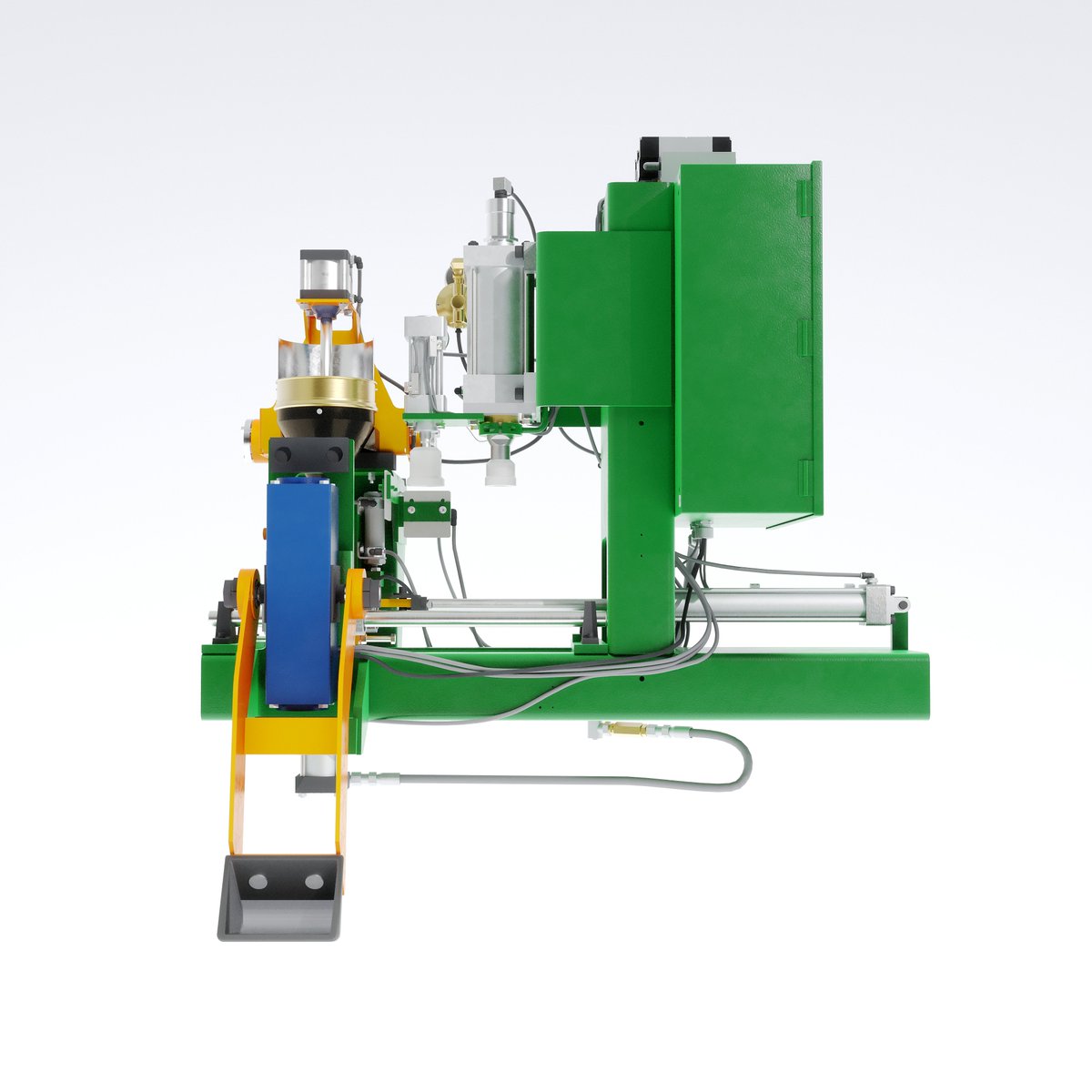

Foundries choose the Simpson Speedmullor® for consistent sand, higher throughput & lower bentonite use—fewer defects, real savings. It’s not just a mixer, it's a muller with a competitive edge. #SimpsonSpeedmullor #GreenSand

0

0

0

Productivity = Competitive Advantage.The Simpson Speedmullor® delivers true mulling—not just mixing. ⚙️ Stronger sand.⚙️ Shorter cycles.⚙️ Smaller footprint.⚙️ Lower energy costs. High-performance mulling that pays off. #SimpsonSpeedmullor #GreenSand

0

0

0

🔧 Minimize downtime. Maximize performance. Keep critical OEM spare parts on hand to prevent delays, protect your process, and extend the life of your Simpson equipment. Be ready—stock up today. #SimpsonParts #OEMParts #PreventDowntime #SmartMaintenance

0

0

1

🔧 See How It Works.Our YouTube videos are a great resource for foundries + new team members to understand Simpson equipment + green sand systems. From cooling to reclamation—get a closer look at the process. 🎥 Watch & subscribe: #Foundry #HowItWorks

0

0

0