loeschegroup

@LoescheGroup

Followers

14K

Following

896

Media

7K

Statuses

19K

Global market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries, since 1906.

Duesseldorf, Germany

Joined June 2012

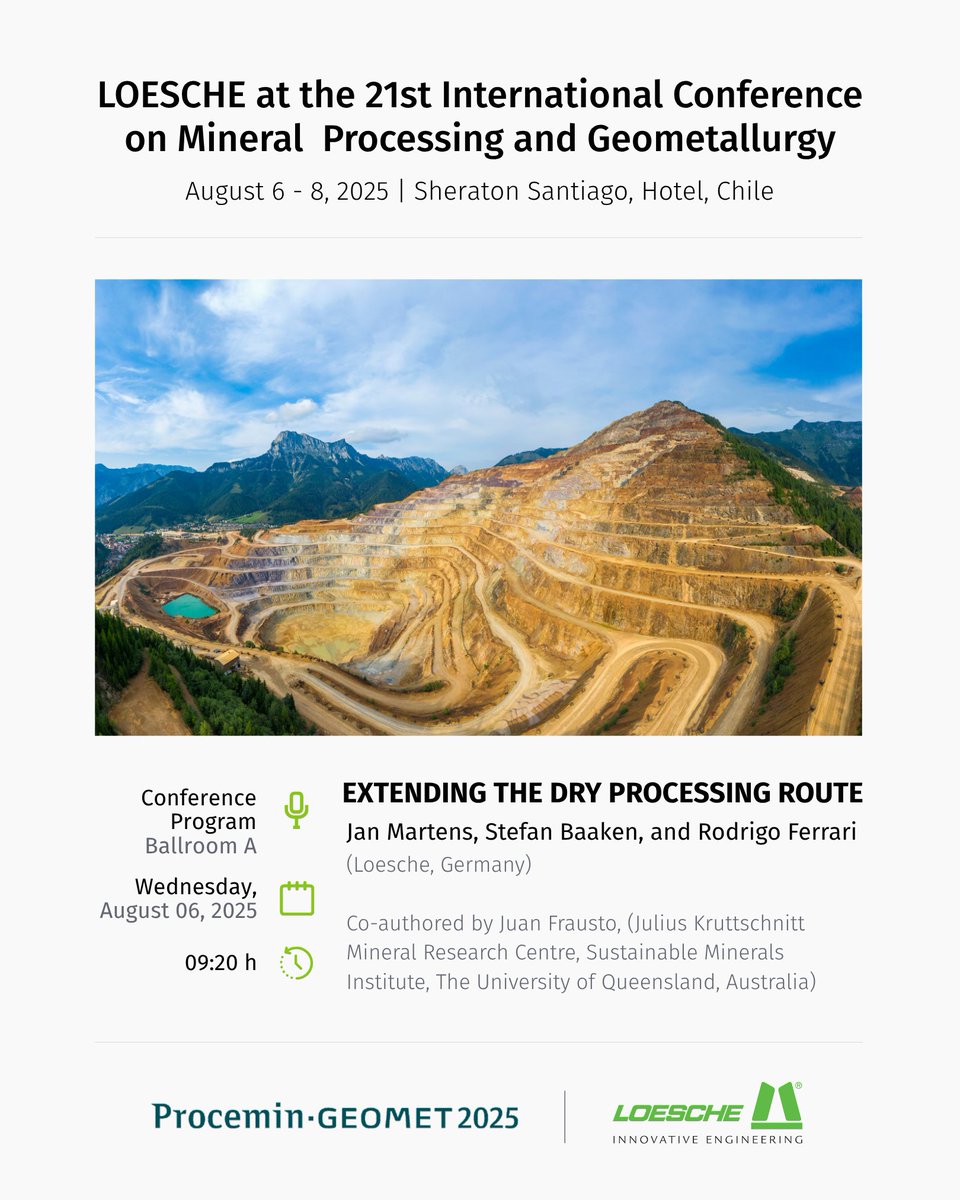

LOESCHE at Procemin Geomet 2025 | Analyzing best practices and innovations in mineral processing and geometallurgy. 📅August 6 - 8, 2025.📍Sheraton Santiago, Hotel, Chile. #internationalconferences #mineralprocessing #geometallurgy

0

0

0

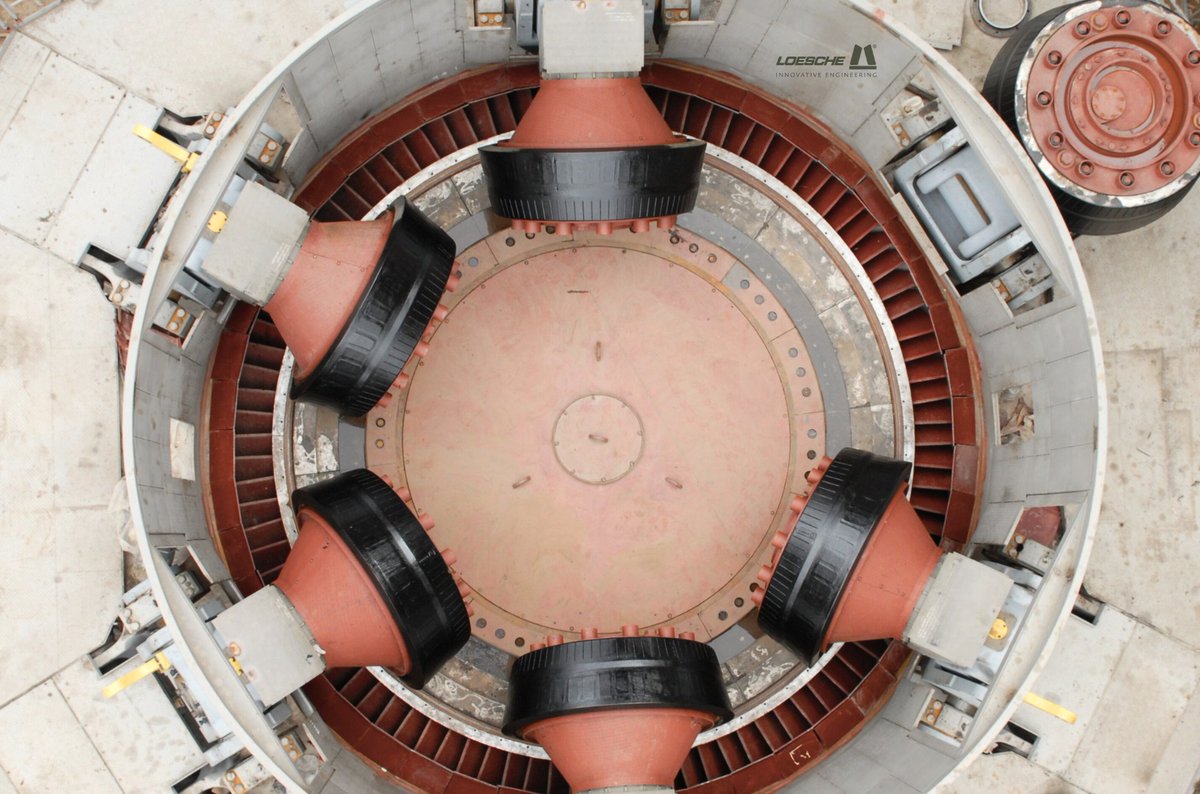

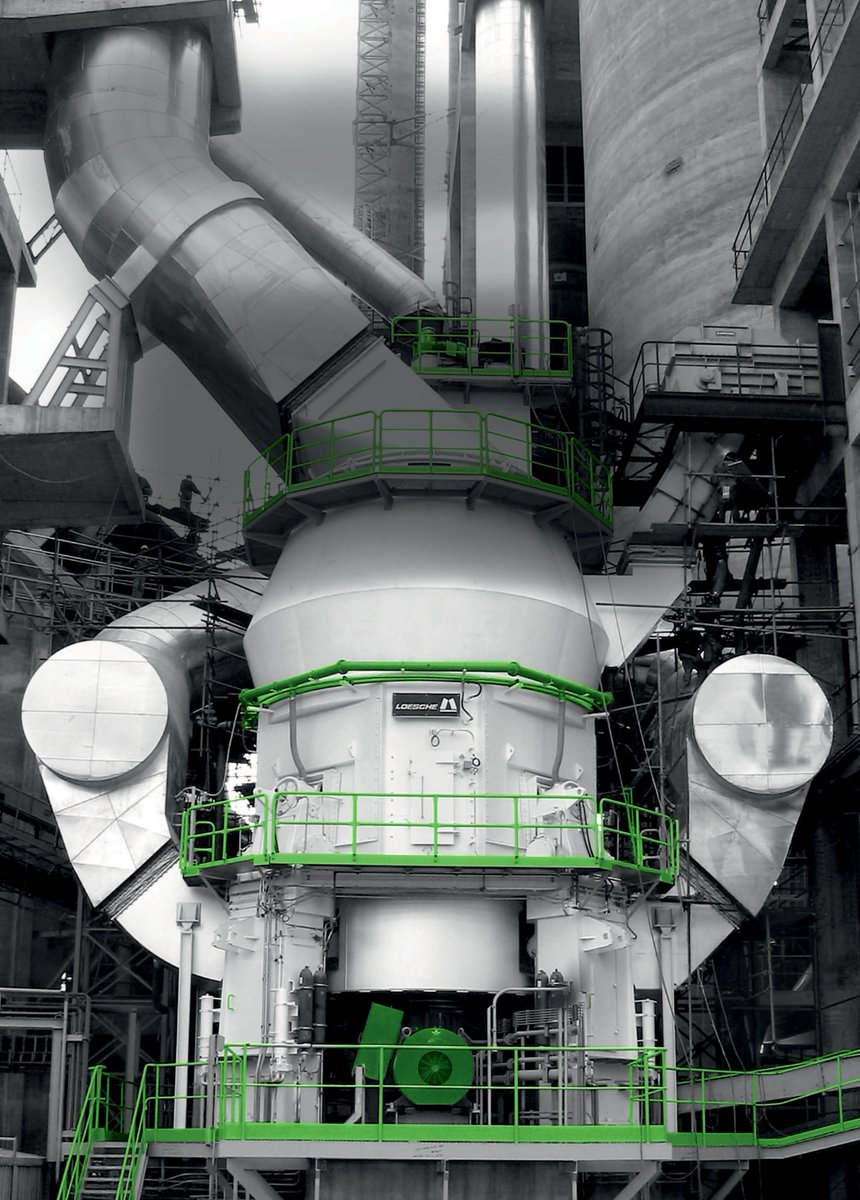

Where #efficiency is a priority, the #mill defines what the system can accomplish. Its design supports mechanical durability, energy performance, and consistent output. Still, true results depend on more than selection alone. #cementindustry

0

1

3

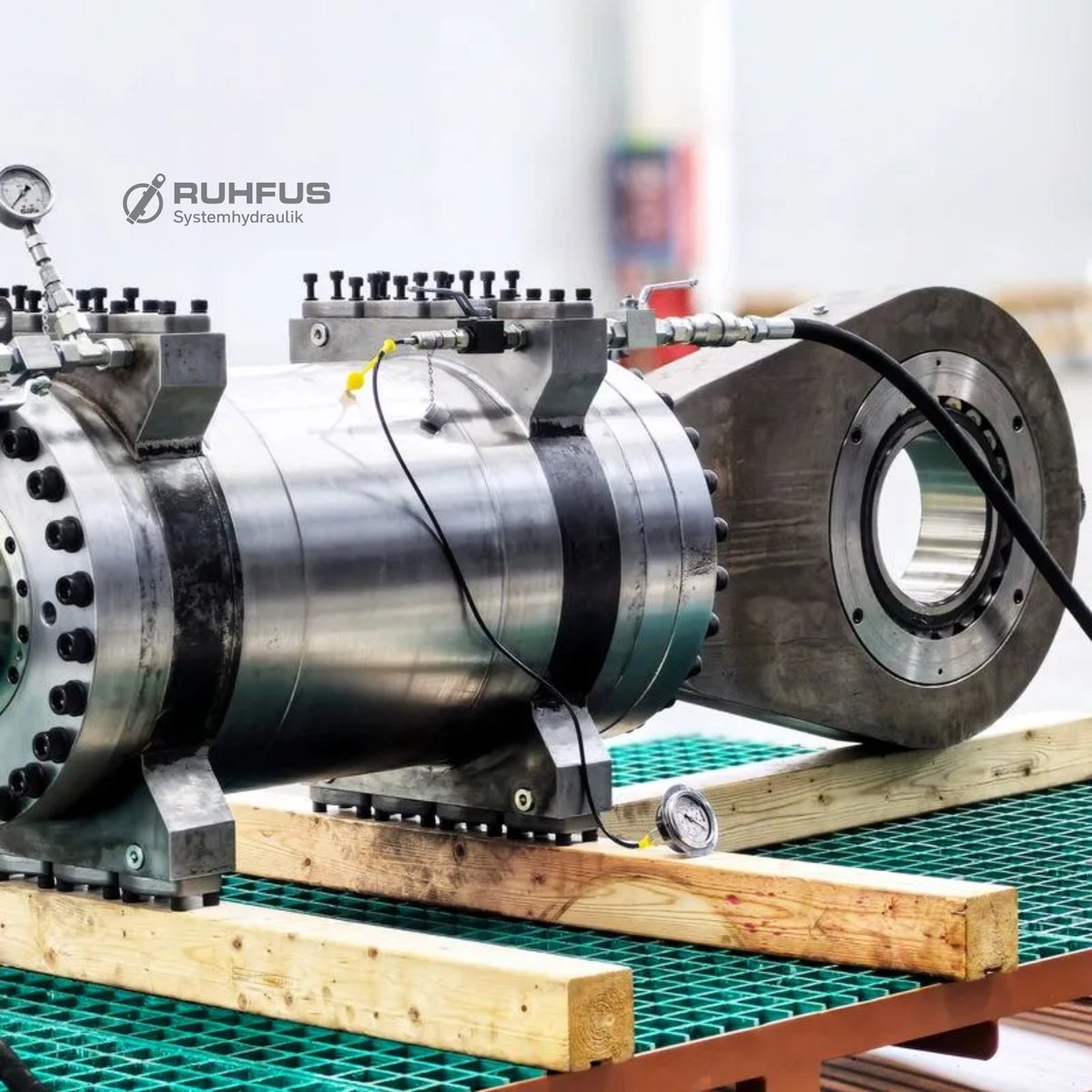

Precision that adapts over time. In complex systems, adaptive precision is the most valuable trait. It allows hydraulic motion to remain consistent, even when the rest of the structure is in motion. #RUHFUS #hydraulics #verticalrollermill

0

0

0

#Verticalrollermills have always aimed to reduce waste and increase process control. But the #GreenKeySolutions take this further, offering a system-wide approach to reducing CO₂ emissions across key stages of #cementproduction.

0

1

1

What holds a #system together?.Processes rarely depend on a single #breakthrough. They depend on thousands of sequential #adjustments, a better way to control flow, and mechanisms that perform a task so well that others don't need to compensate.

0

0

0

#Verticalrollermill technology provides more than efficiency. Its design adapts to different material behaviors, feed conditions, and process priorities, maintaining this adaptability as a key strength. #grindingtechnology #materialprocessing

0

0

0

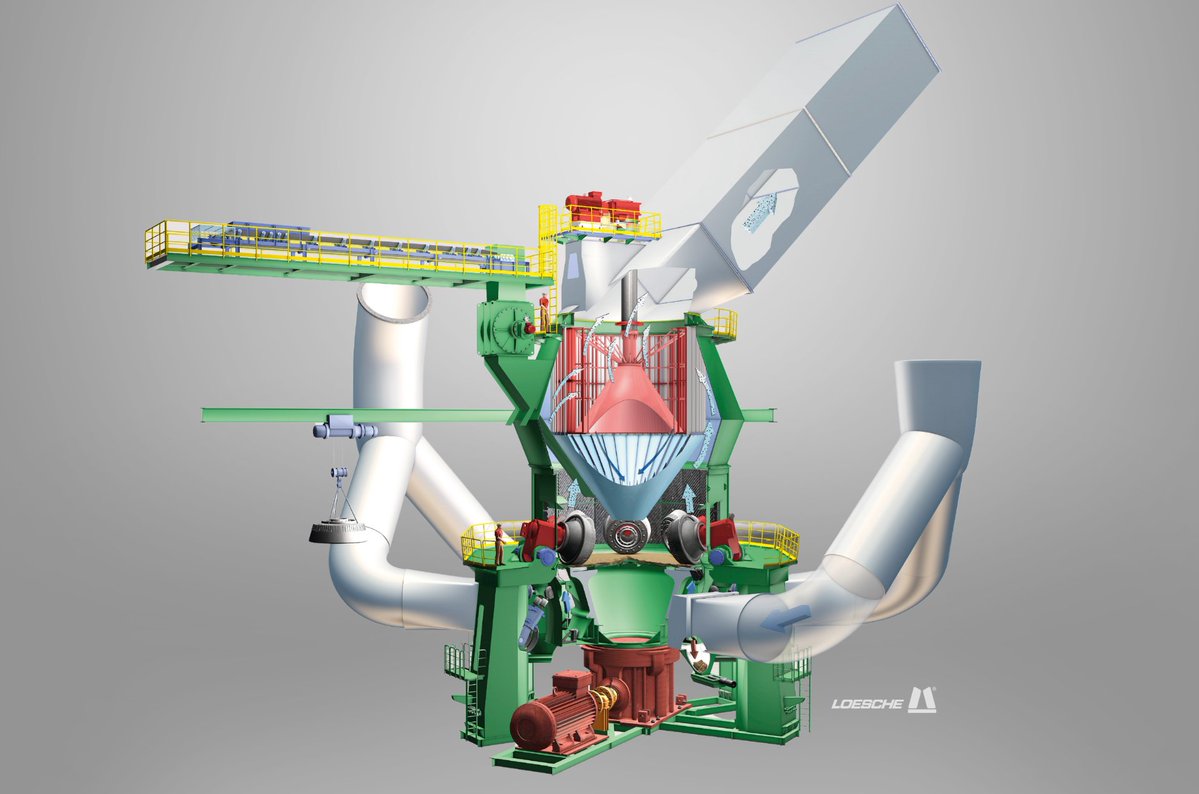

The science of material transformation through #aerodynamics. Airflow defines the rhythm of #verticalgrinding, carrying, drying, and separating material in a continuous cycle. In LOESCHE mills, airflow moves through every stage with a #purpose.

0

1

3

Nearly a century ago, LOESCHE introduced the first #verticalrollermills to grind #cement clinker. At the time, the idea of grinding material between a rotating table and rollers, without horizontal movement, was a break from #tradition. But it worked.

0

1

1

Every motion inside a #verticalrollermill has a role. Some transfer material, others manage pressure. But a few, like the stroke of a hydraulic cylinder, determine the entire process stability. #hydrauliccylinders #grindingtechnology

0

0

0

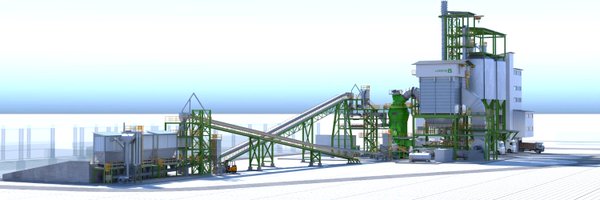

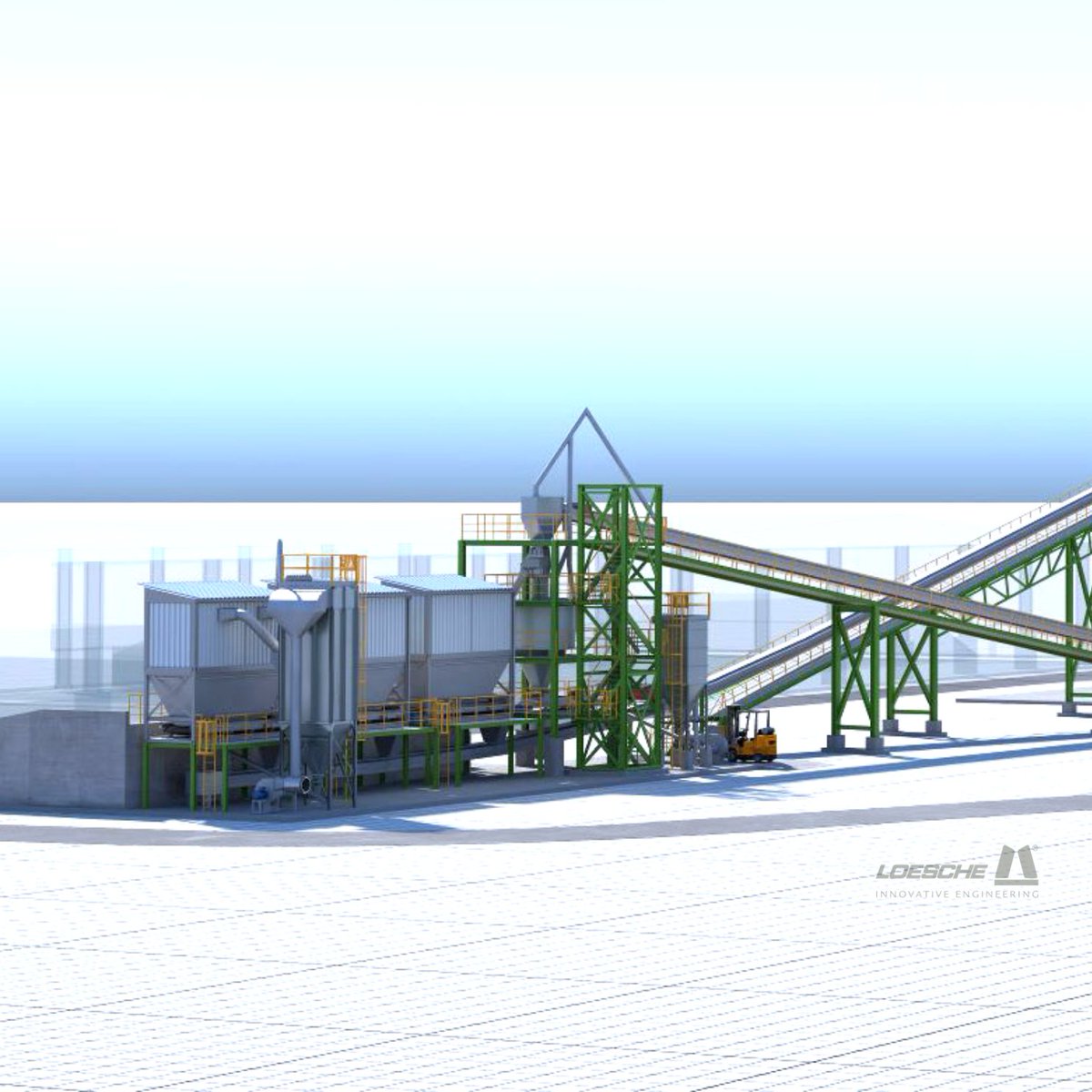

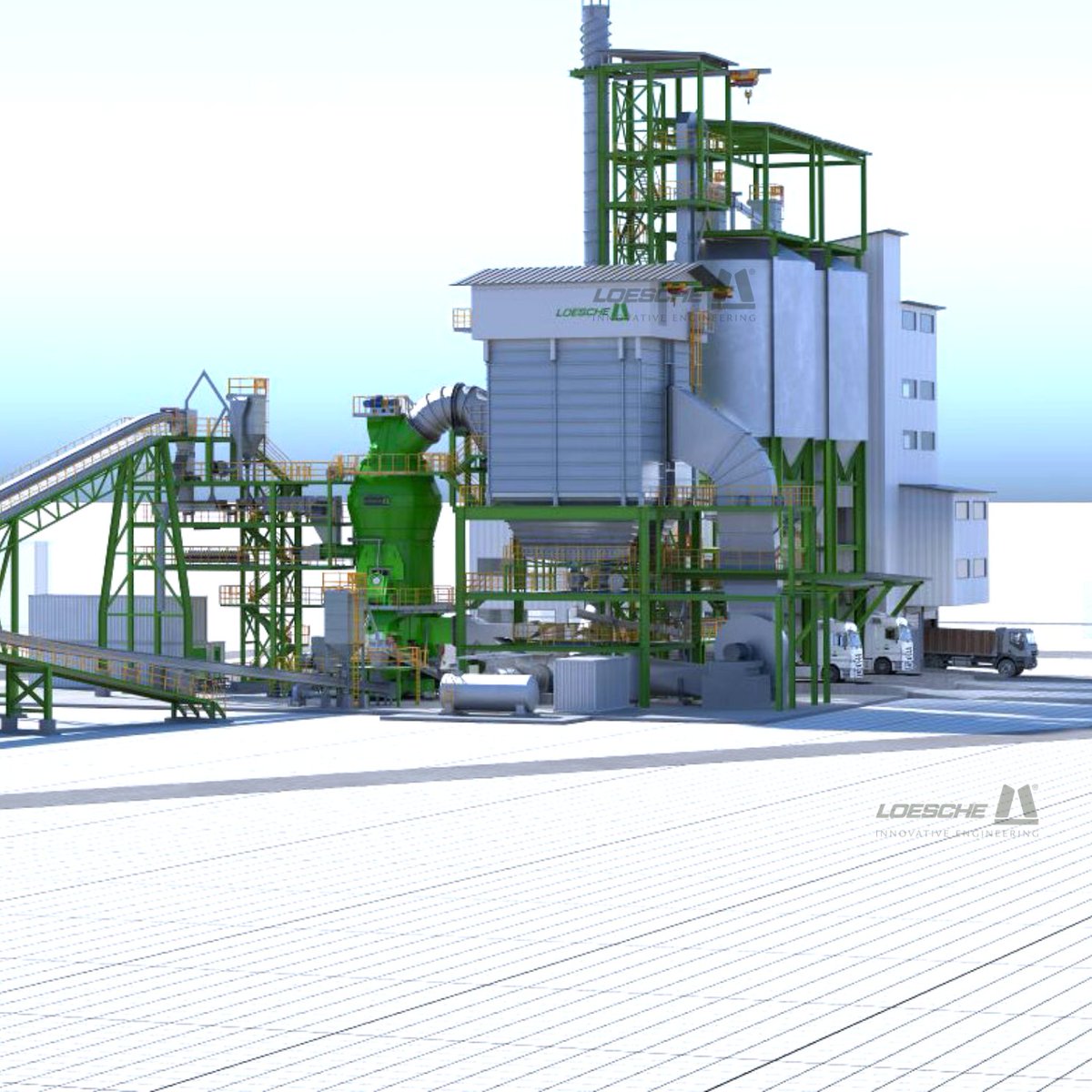

#Plantdesign is often evaluated based on capacity or output. However, a true measure of effectiveness lies in how space is used. In this configuration, every level, platform, and transition point serves a #purpose. #industrialarchitecture

0

1

1

The role of any technology is to accomplish its original purpose, and then open the door to new #advances and alternative applications. #Grindingtechnologies are no different in that each upgrade brings a new approach to #mineralprocessing.

0

0

0

Something subtle happens between 600 and 900°C. #Kaoliniticclays, once inert and layered, transform into reactive #metaclays: pozzolanic, amorphous, and useful. Unlike clinker, there’s no carbonate to decompose or no CO₂ to release. #calcinedclay

0

0

1

In #verticalrollermills, stability and adaptability are essential, relying on the cylinder’s #precision in returning to the same position thousands of times. Guidance, sealing, surface finishing, and wear margins ensure #continuity under load over time.

1

0

1

In the LOESCHE #verticalrollermill system, once comminution is complete, the product is no longer on the clock. Stored in silos, dry-ground ore becomes temporally #flexible, unlinked from the rhythms of extraction or energy supply. #drygrinding

0

1

2

For centuries, #engineers have looked to nature’s patterns for inspiration. They #experimented with new ideas and blended time-tested methods with fresh thinking. Today, the flow of material through every #verticalmill design follows that same approach.

1

1

3

The space between pressure and process. In every vertical grinding system, a balance is maintained between rollers and feed, air and fines, motion and resistance, and pressure and precision. #systemdesign #drygrinding #pressurecontrol

0

0

1

Designing for wear is a new standard. At #MEDCEM’s Silifke Plant, the precision hardfacing of #verticalrollermill components reflects a design philosophy where #maintenance is not an afterthought but a built-in function of the system.

0

0

1

While some #technologies scale by growing larger, others scale by becoming more #adaptive. Our modular #plantarchitecture does the latter, bringing not just machinery, but also expertise, to the places where cement meets geography, regulation and time.

0

0

0

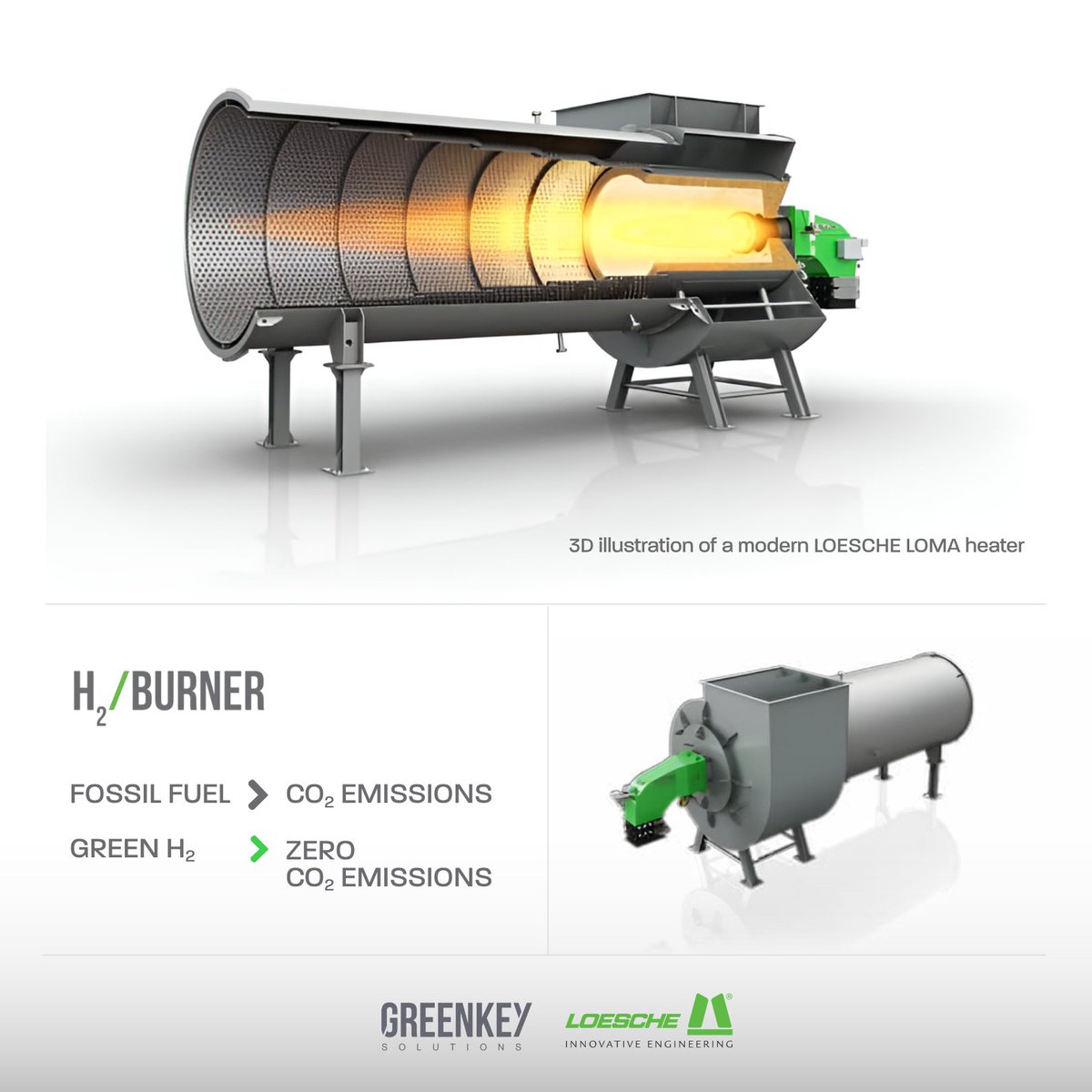

What would happen when we stopped burning carbon to make heat?. Our H₂/BURNER #GreenKeySolution makes it technically viable to deliver the same thermal performance without carbon, both for new installations and retrofit applications. #cementindustry

0

0

1