Linde Engineering

@LindEngineering

Followers

3K

Following

384

Media

275

Statuses

995

Your partner for the production and processing of gases.

Munich

Joined March 2010

#LindeEngineering puts petrochemicals on a CO₂ diet. At the top of the list is the Steam Cracker - embedded in a holistic solution on the way to net-zero. Find out how we’re working on this goal:.

1

1

10

Can a zero be promising? When it comes to CO₂ emissions, yes! Learn more about why the #petrochemistry industry needs a holistic roadmap to zero emissions as an important step to #sustainability in our latest success story #GasProcessing #efficiency

1

1

6

In the 1960s, Linde was the first company to implement the continuous recovery of #acetylene in a commercial steam cracker. Since then, we refined the design to meet the demands. It can be integrated with any #steamcracker technology. #LindeEngineering

1

1

6

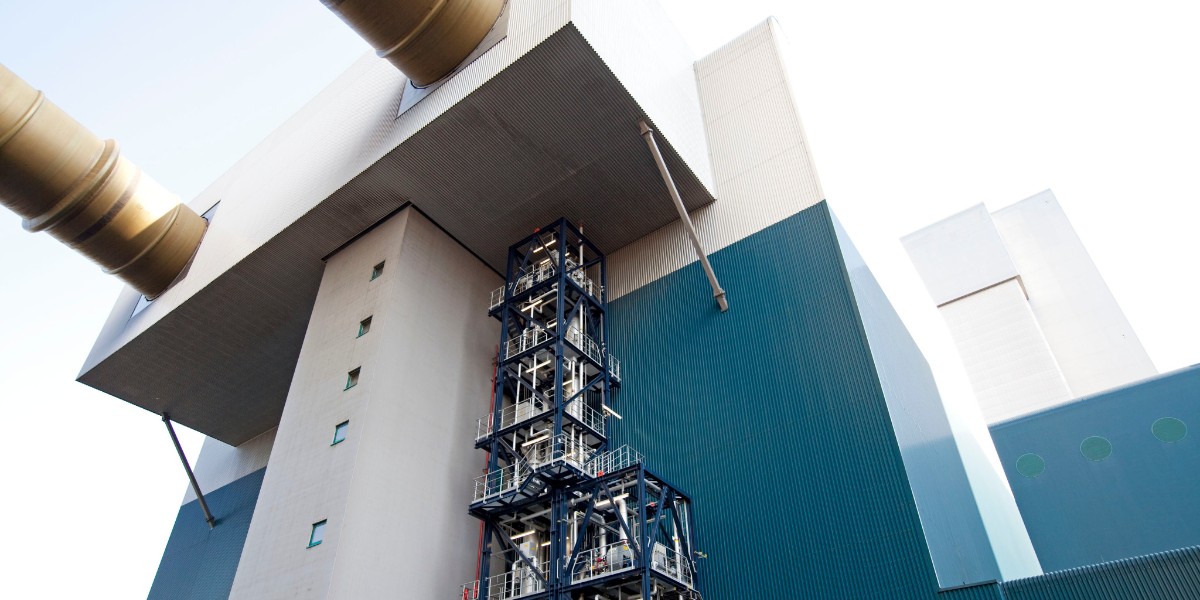

Emission-intensive industries have a hard time meeting the targets of the Paris Agreement on climate change. Technologies for #carboncapture, utilization, and storage (CCUS) provide the most significant results. Learn more. #LindeEngineering.

0

1

6

About 35 percent of industrial CO2 #emissions come from burning fossil fuels to generate high-temperature heat. #LindeEngineering constructs and retrofits plants with equipment and infrastructure for carbon capture.

0

1

8

Linde has 60 years of experience with #acetylene recovery. Benefits of our processes and technology:.✔ extremely pure ethylene streams.✔ no fouling or corrosion problems.✔ flexibility for all plant operating cases .#LindeEngineering #ProcessingPlants

0

1

6

There are 6 years left on the carbon clock. Mankind’s CO2 -#emissions are on track to take the atmosphere over the 1.5°C threshold by 2030. #Carboncapture technologies are an answer to this challenge and can be divided into three categories.

0

0

2

To debottleneck the Claus units at a refinery in Gdańsk, Linde proposed a gas-enabled solution to increase capacity through oxygen enrichment. Linde delivered a containerized, turnkey VSPA unit that supports on-site oxygen enrichment in refineries. #AirSeparation #Sustainability

0

2

5

The requirements of operators of public network stations are perfectly met by our refueling solutions. Hydrogen refueling stations (HRS) with small footprints can be simply incorporated into already existing gas stations. Find out more: #GreenHydrogen

0

4

16

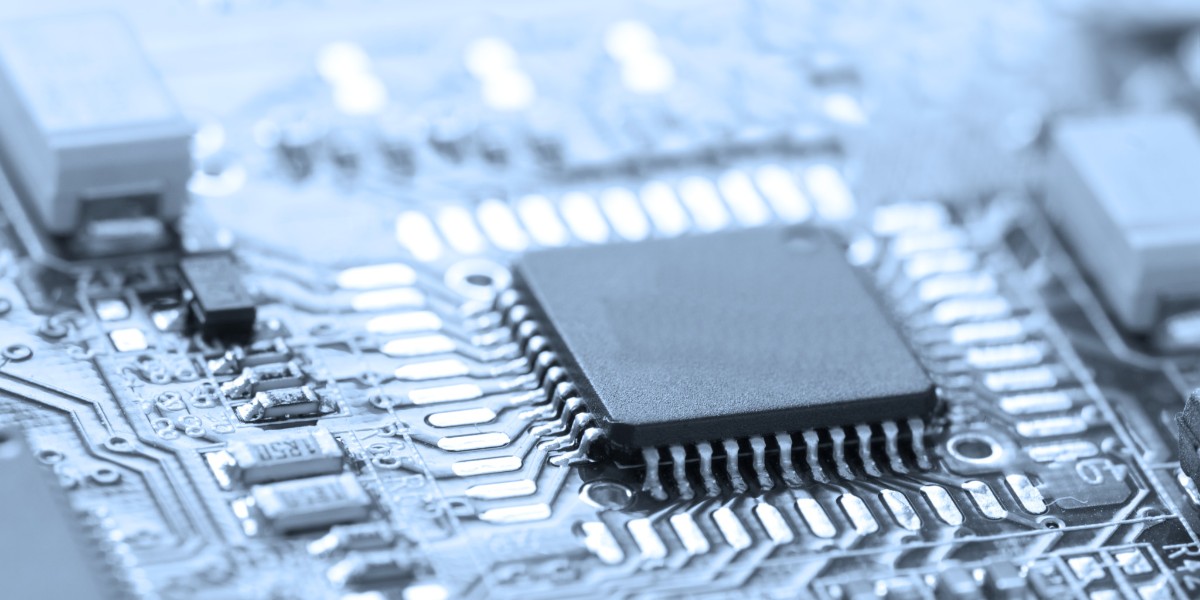

We bet you don’t know all the application fields of #hydrogen: the electronics industry relies on high-purity hydrogen for semiconductor manufacturing while chemicals customers need H2 for fuel desulfurization or #hydrotreatment. Discover more:

1

2

9

Linde built two #ASU s for the Kalinganagar industrial complex in India. It supplies Tata Steel, one of the world’s largest steel manufacturers, with over 4,000 tpd of gaseous oxygen, nitrogen, argon and produces liquid gases for regional markets. #AirSeparation #Sustainability

2

0

3

To enable widespread adoption of clean #hydrogen, Linde is investing heavily into alternative production methods at Leuna. Next on the list is to build and operate the world’s largest electrolysis plant. Learn more about this mission: #Sustainability

1

1

10

The Bazhong Phase II LNG plant in China features Linde’s patented LiMuM™ technology and can process 1.3 million cubic meters (Nm³) of feed gas per day – our contribution to the clean energy industry in China. #Sustainability

0

0

9